How do LCD TFT Displays and OLED Displays Work?

How do the Different Types of Component Displays work?

Monochrome Liquid Crystal Displays (LCDs) are composed of two glass panels with electrodes printed on the interior surfaces. Encased between these glass layers is a liquid crystal (LC) organic fluid. When the LCD is in its “off” state, meaning no voltage is applied, light passes through the display. However, in the “on” state, when voltage is applied, the LC fluid twists in response to the electric field, resulting in the blocking of light and the creation of dark areas on the LCD. By selectively applying voltage to the electrodes, various patterns can be generated. It’s important to note that LCDs are passive displays, meaning they do not emit their own light. Instead, they rely on ambient light in the surroundings or backlight illumination from sources like LED, Electroluminescent (EL), or Cold Cathode Fluorescent Lamp (CCFL) lighting.

LCD Backlighting

An LCD essentially functions as a reflective surface and requires a light source to make the displayed content visible. This can be achieved by utilizing available ambient light or by adding a backlight source positioned behind the LCD. There are several backlighting options available, but the primary three are as follows:

1. Electroluminescent (EL) Backlighting: EL backlights are extremely thin, lightweight, and provide consistent illumination. They come in various colors, with white and turquoise blue being the most popular choices for LCDs. Although their power consumption is low, they require voltages in the range of 80-100VAC, which are typically supplied by an inverter converting a 5, 12, or 24VDC input to AC output. ELs have a relatively low brightness of 15-20cd/m² and a limited lifespan of 10,000 to 15,000 hours to reach half brightness.

2. Light Emitting Diode (LED) Backlighting: LEDs have become the top choice for backlighting LCDs. They are available in a wide range of colors, including white and blue, and offer high brightness levels with a long operational life, typically ranging from 25,000 to 50,000 hours, depending on the color. These solid-state devices operate directly off 2-5VDC, though a current limiting resistor is advisable for LED protection. LEDs are either mounted in an array directly behind the LCD or along one edge within a diffuser assembly.

3. Cold Cathode Fluorescent Lamp (CCFL) Backlighting: CCFL backlighting offers low power consumption and produces a bright white light. Typically, CCFL lamps are positioned along the edges of the LCD with a diffuser assembly to evenly distribute the light across the rear of the display. CCFL lamps require 270-300VAC, supplied by an inverter that converts 5, 12, or 24VDC input to AC.

Viewing Modes

LCDs are available in three fundamental light transmission modes:

Reflective Mode: This mode utilizes available or ambient light to illuminate the display by incorporating a reflector along with the rear polarizer. Reflective LCDs are best suited for outdoor or well-lit environments.

Transflective Mode: Transflective LCDs combine reflective and transmissive features, with the rear polarizer having partial reflectivity. They are designed to be used with a backlight for visibility in all lighting conditions.

Transmissive Mode: In this mode, LCDs have a transparent rear polarizer and do not reflect ambient light. To view the display, the backlight must be active at all times. This mode is most effective in low-light or dark conditions.

OLED (Organic Light-Emitting Diode) Displays:

Organic Materials: OLED displays use organic compounds that emit light when an electric current is applied. These organic materials are sandwiched between two electrodes, usually one being transparent.

No Backlight: Unlike LCD displays, OLED displays do not require a separate backlight. Each pixel in an OLED display emits its own light.

Pixel Control: OLEDs are capable of pixel-level control. When an electric current is applied to a specific pixel, that pixel emits light, while neighboring pixels remain dark.

Color Emission: OLED displays can produce colors by using different organic materials that emit light at different wavelengths. Red, green, and blue subpixels can be combined to create a full range of colors.

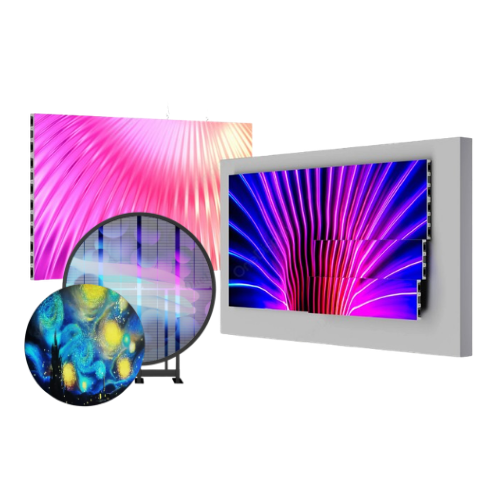

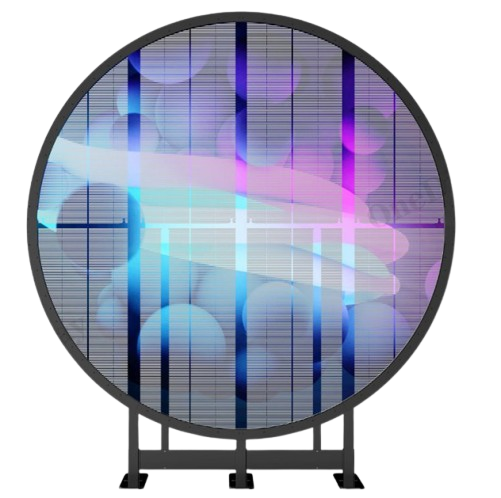

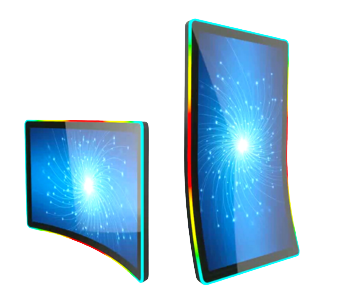

Flexible and Thin: OLED displays are thin and lightweight, and they can be made flexible, allowing for curved and foldable displays.

Fast Response Time: OLEDs have a fast response time, making them suitable for applications where fast motion is involved, such as in gaming.

- Colour LCD (CSTN Liquid Crystal Display)

CSTN, colour super-twist nematic or passive LCD utilizes the same technology principles as Monochrome LCD (please see previous text) however instead of one dark pixel, with the use of colour filters each pixel in a CSTN display is broken down into a group of three dots, one red, one blue and one green generally arranged in a stripe formation. The LCD drive electronics applies a varying voltage depending on the colour required to all three coloured dots which untwist the liquid crystal allowing the exact amount of light through on each coloured dot to give the desired colour or shade. CSTN LCD can offer a maximum colour palette of 65k colours and are ideal for industrial applications requiring colour but not necessarily requiring extremely fast moving images.

- Colour TFT LCD (Thin Film Transistor)

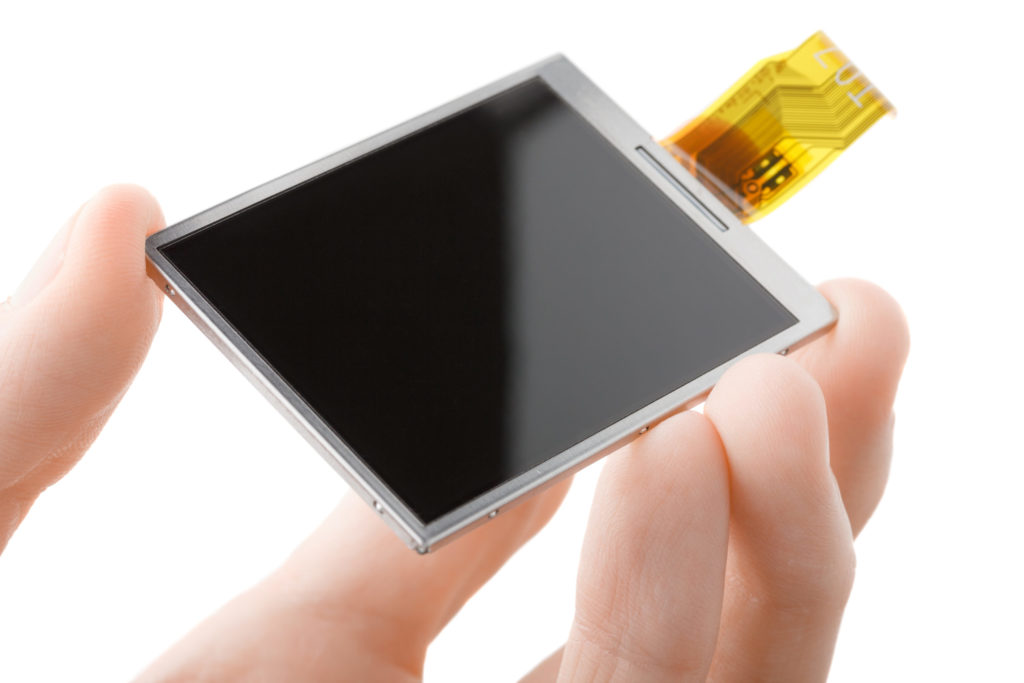

Thin Film Transistor LCD basically describes the control elements that actively control the individual pixels, which has coined the term “Active Matrix LCD”. Each pixel is again broken down into three dots, red, green and blue which are produced by colour filters and are arranged in either a stripe or delta formation, each dot is driven by one transistor i.e. three transistors per one pixel. The liquid crystal in its “off” state no voltage applied will block all light coming through from the backlight, but when a voltage is applied across the liquid crystal elements they twist by up to 90° allowing a level of light through, the transistors control this degree of twist and hence the intensity of the red, green and blue elements of each pixel forming the image on the LCD. TFT LCD are ideal for all applications requiring fast switching colour images.

- OLED (Organic Light-Emitting Diode)

The basic structure of an OLED or OEL (Organic Electroluminescence) is a sandwich formed with a thin, transparent semi-conducting anode made from Indium Tin Oxide and a metal based cathode on both sides of an organic substrate. The organic material comprises of a hole transmission layer (HTL), an emitting layer (EL) and an electronics transmission layer (ETL). The emissive EL layer includes a polymeric substance that allows the deposition of the organic compounds in rows and columns on a flat carrier (usually glass) by using a simple printing method to create a matrix of pixels. When the correct voltage is applied holes injected in the anode and the electric charge from the cathode are drawn together and combine in the emissive layer, which causes the pixel to emit light. One of the major benefits of OLEDs over more traditional displays is that because they emit light they do not need a backlight which makes them ideal for battery powered applications.