+44 (0)1634 791600

info@crystal-display.com

Newsletter Sign Up!

+44 (0)1634 791600

info@crystal-display.com

Discover the diverse selection of industrial monitors and Panel PCs meticulously crafted by Crystal Display Systems, tailored specifically for ATEX applications. Our comprehensive range offers unparalleled flexibility, allowing for extensive customization to meet your unique requirements. Whether you need high brightness backlights, bespoke touchscreens, or integrated embedded systems, we have the solution.

Each of our products undergoes rigorous testing to guarantee compliance with the stringent standards of Class I Div 2 and Class I Zone 2 areas. Equipped with Ethernet and WiFi as standard features, along with a variety of operating voltages to choose from, our monitors and Panel PCs ensure seamless integration into your ATEX environment. Rest assured, our adherence to standards such as IEC 60079-0, IEC 60079-11, and IEC 60079-15 solidifies our commitment to safety and quality, providing you with reliable solutions for hazardous settings.

The oil and gas industry now relies more than ever on industrial monitors, driven by a growing focus on safety and operational efficiency. CDS rugged displays are designed to withstand the demands of all major oil and gas sectors, ensuring reliable performance in extreme conditions.

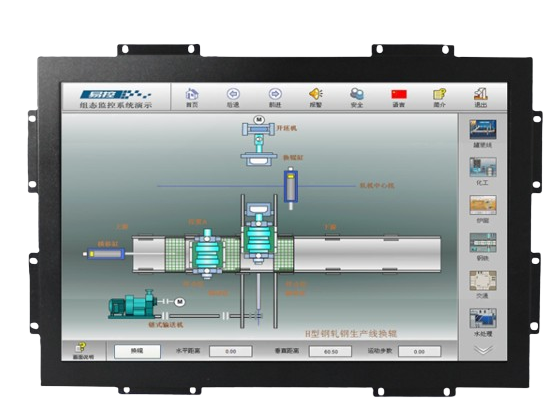

Displays for gas and oil applications must meet stringent requirements for safety, durability, and visibility in hazardous environments. Common types include ruggedized industrial monitors, explosion-proof displays, ATEX-certified displays, sunlight-readable displays, touchscreens with protective layers, and customized solutions. These displays are essential for providing clear visual information and human-machine interaction in oil refineries, drilling rigs, and other hazardous locations while ensuring compliance with industry standards and regulations.

Rugged Construction: Built to withstand harsh environmental conditions, including dust, moisture, vibration, and extreme temperatures.

Explosion-Proof Design: Prevents ignition of flammable gases or vapors within the display enclosure, ensuring safety in hazardous locations.

ATEX Certification: Compliance with ATEX standards for equipment used in potentially explosive atmospheres, essential for European markets and other regions where ATEX regulations apply.

Sunlight Readability: High brightness levels and anti-reflective coatings ensure clear visibility in outdoor environments with direct sunlight.

Touchscreen Functionality: Enables human-machine interaction for controlling and monitoring processes, often with ruggedized touchscreens and protective overlays.

Customization Options: Tailored solutions to meet specific size, mounting, and functionality requirements of oil and gas applications.

Compatibility with Hazardous Area Classifications: Suitable for use in Class I Div 2, Class I Zone 2 areas, with Ethernet, WiFi, and a choice of operating voltages for seamless integration into ATEX environments.

Compliance with Standards: Stringent testing to ensure compliance with industry standards such as IEC 60079-0, IEC 60079-11, and IEC 60079-15, ensuring safety and reliability.

Gas & Oil rig environments are often exposed to vibrations, shocks, and extreme temperatures. CDS LCD monitors designed for these applications have ruggedized construction to withstand these conditions and ensure durability.

To protect against dust, moisture, and corrosive substances commonly found on oil rigs, Our monitors come with sealed enclosures with high IP (Ingress Protection) ratings. This ensures that internal components are shielded from environmental damage.

Touchscreen LCD monitors provide intuitive and user-friendly interfaces, allowing operators to interact with the display even while wearing gloves or protective gear commonly used on oil rigs.

Drilling Rigs: Monitoring drilling operations, displaying real-time data, and controlling equipment remotely.

Oil Refineries: Monitoring and controlling refining processes, displaying process parameters, and providing alerts for abnormal conditions.

Pipeline Monitoring: Displaying pipeline flow rates, pressure levels, and detecting leaks or abnormalities along the pipeline.

Tank Farms: Monitoring tank levels, temperatures, and pressures, as well as managing tank farm operations.

Offshore Platforms: Providing visual feedback for offshore drilling and production operations, as well as monitoring safety systems.

Chemical Plants: Displaying chemical process parameters, controlling equipment, and monitoring safety systems to ensure compliance with regulations.

Pump Stations: Monitoring pump performance, flow rates, and pressure levels in oil and gas transportation networks.

Emergency Response Centers: Displaying real-time data from sensors installed in hazardous locations to enable quick response to incidents or emergencies.

Environmental Monitoring: Displaying data from environmental sensors to monitor air quality, water quality, and other environmental parameters in and around oil and gas facilities.

The CDS product line can include ATEX-Ex monitors and ATEX-Ex HMI panel PC’s manufactured from AISI 316L acid resistant stainless steel in rugged fully encapsulated sealed cabinets that are easy to keep clean and sterile. These products are perfect for pharmaceutical manufacturing like in cleanrooms. These CDS products withstand treatment with a long list of cleaning detergents as water, ethanol, and vaporised hydrogen peroxide (VHP), which removes all forms of microbiological life. Operation methods include interactive multi-touch screen even while wearing gloves. This modern technology ensures maximum productivity and user satisfaction. CDS delivers life science and pharmaceutical solutions globally to leading pharmaceutical manufacturers. Based on the experience of numerous installations, Blue Line can put together the solution that meets your requirements in an excellent way.

Besides ATEX-Ex rating, the CDS products are designed to withstand water, dust, and cleaning according to IP65, IP66 or IP67 standards. We Comply with these standards, CDS’s ATEX / Ex Monitor & Computers are ideal for extreme environments requiring ultimate protection: life sciences, pharmaceutical, oil, gas, & various chemical industries. The CDS ATEX and Ex product lines are designed for 24/7 operation, with low power consumption, passive cooling, plus without moving parts for optimal operational reliability. Optimize the workflow as well as safety, comfort, and security. Achieve a significant Return On Investment (ROI) and a competitive solution with CDS high quality reliable products.

Whether your requirements are fixed or mobile the CDS explosion-proof product line is divided in a portfolio for fixed installation and a portfolio for mobility also. The CDS ATEX-Ex Monitors and Human Machine Interface (HMI) Panel PCs for fixed installation can be mounted on machines, control cabinets, walls, ceilings, on adjustable gas suspend arms or pipes. Make use of our competent specialists for configuring ATEX and Ex systems for demanding environments. Reach out to the CDS ATEX experts.