Offering the reliable touchscreen solutions necessary for factory automation

The quest for increased efficiency, quality, and safety has led companies to embrace innovative technologies when it comes to modern manufacturing in factory automation. Crystal Display Systems (CDS) emerges as a key player, offering cutting-edge display solutions and touchscreens designed specifically for factory automation. In this blog post, we’ll explore how CDS’s industrial monitors with integrated touchscreens are transforming the manufacturing sector and paving the way for Industry 4.0.

The Role of Information in Factory Automation

At the heart of factory automation lies the crucial process of information gathering, analysis, and monitoring. These elements are paramount for optimizing various aspects of production, including efficiency, quality assurance, and safety protocols. CDS recognizes the significance of these factors and addresses them through its advanced display solutions.

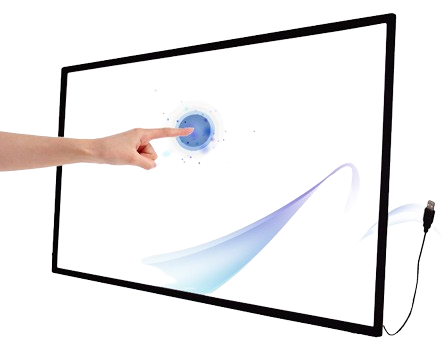

Power of Industrial Monitors with Touchscreens

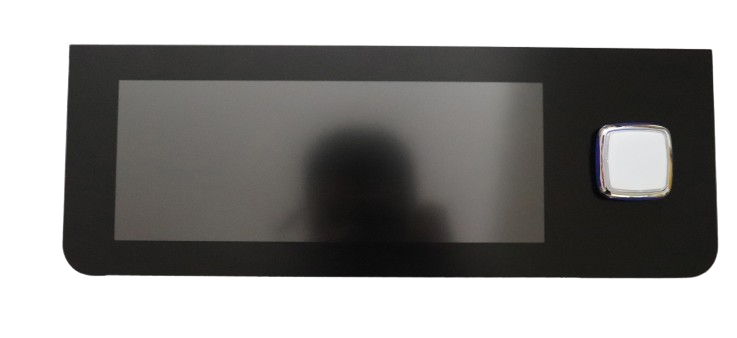

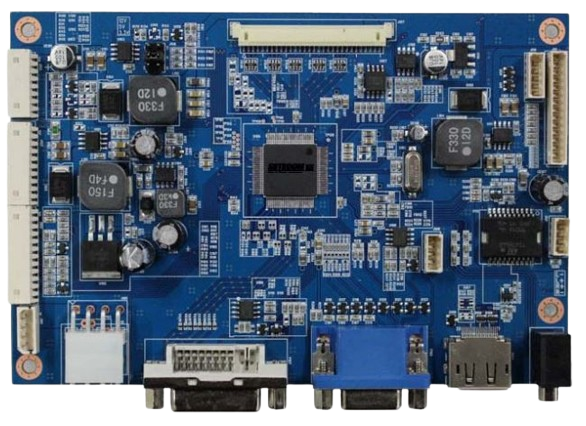

To provide a user-friendly approach to displaying complex real-time information, CDS integrates touchscreens into industrial monitors. This combination offers a powerful and cost-effective solution for operators to interact with the production line. When coupled with embedded single-board computers (SBC) and appropriate software support, these systems become IoT and AI ready, aligning seamlessly with the Industry 4.0 paradigm.

Real-time Monitoring and Control

Fully integrated interactive monitor solutions empower factories to display comprehensive information about the production line in real-time. Operators can control machinery directly from the same device, using touch technology or integrated buttons. The addition of intelligence to these systems allows for autonomous decision-making, further enhancing overall productivity.

Building a Smart Factory Environment

CDS’s display solutions set the foundation for smart factory environments by facilitating accurate data gathering and analysis across machines. This results in more efficient processes, delivering higher quality at a lower cost in an accelerated manner. The real-time capabilities also enable quick responses to ensure the safety of personnel, prevent equipment damage, and minimize downtime.

Enduring Harsh Factory Environments

Factories are harsh environments with extreme temperatures, humidity, and intense shock and vibration. Production line equipment is expected to endure these conditions for extended periods. CDS addresses this challenge by selecting industrial TFT panels with wide environmental specifications, ensuring that the display component can withstand these demanding conditions. Additionally, other critical components such as touchscreens, housing, power supply, and embedded systems are rated to prevent monitor failure.

Custom Solutions for Unique Applications

Understanding that every application is unique, CDS offers custom monitor solutions. This approach allows for physical modifications to display, glass, touch, embedded systems, or controllers, and housing to meet exacting standards, seamlessly integrating into specific applications.

CDS’s expertise and robust supply chain ensure product compatibility and availability for at least five years. This commitment to long-term support is crucial in the ever-evolving landscape of technology. On a project-by-project basis, CDS evaluates hardware, software, and support requirements for IoT and AI integration, creating intelligent systems tailored to individual needs.

Need More Information?

CALL US +44 (0)1634 791600