How CDS are the Extreme Temp Pros

When designing Touchscreens for Extreme Operating Conditions, reliability is not optional — it is engineered.

At Crystal Display Systems (CDS), we work closely with design engineers developing systems for industrial automation, transportation, outdoor digital signage, marine environments, defence, and mission-critical embedded applications. These environments expose display systems to sustained stress that would rapidly degrade standard commercial-grade screens.

This article explores the engineering principles behind robust Touchscreens for Extreme Operating Conditions — and how CDS supports customers with proven, field-ready solutions.

What Defines Extreme Operating Conditions for Touchscreens?

Extreme operating conditions rarely involve just one stress factor. Instead, they combine multiple environmental challenges, including:

Wide temperature ranges (e.g. -30°C to +85°C or beyond)

Rapid thermal cycling

High humidity and condensation

Mechanical shock and vibration

Electromagnetic interference (EMI)

Dust and water ingress (IP-rated environments)

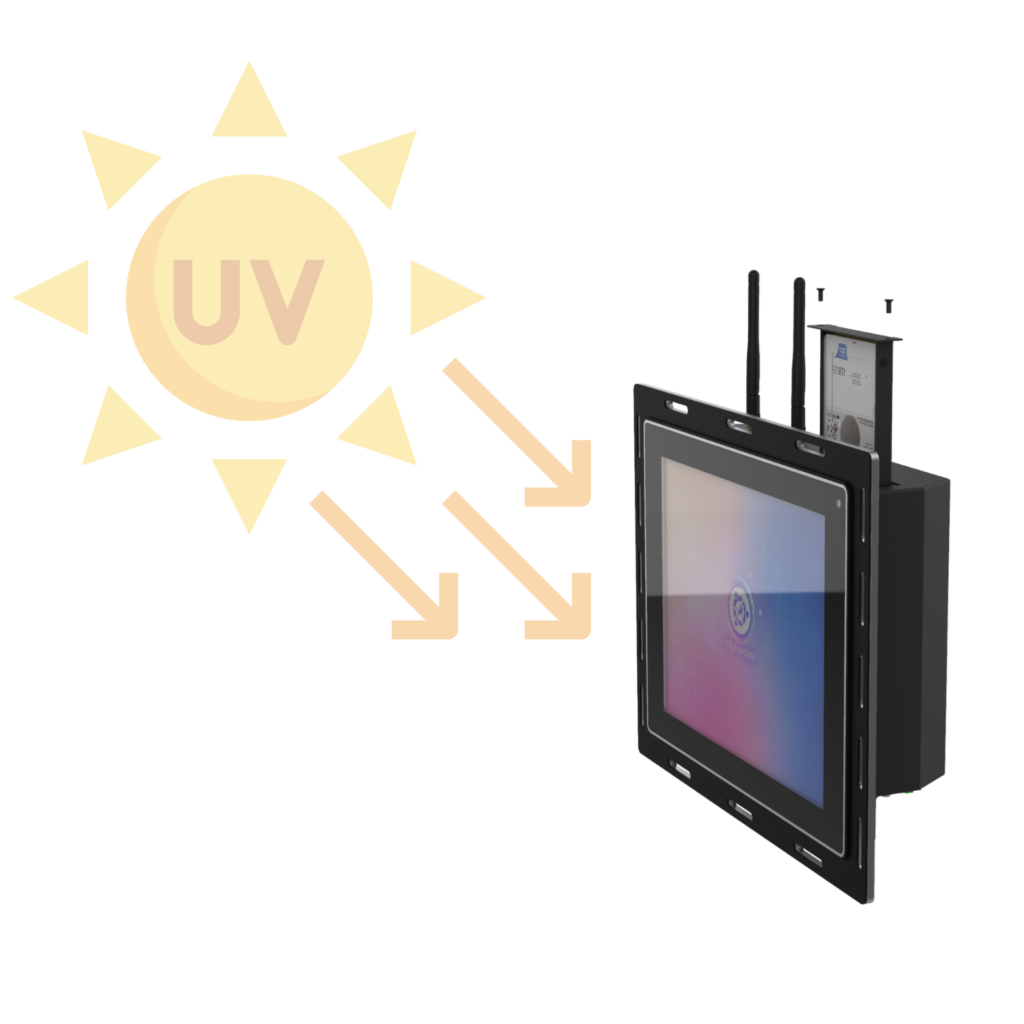

UV exposure and solar loading

Chemical exposure

Designing Touchscreens for Extreme Operating Conditions requires consideration of the cumulative effect of these stresses on optical clarity, electrical stability, and long-term mechanical integrity.

Material & Optical Stack Engineering

The optical stack is critical to ensuring durability in harsh environments.

Key engineering decisions include:

Chemically strengthened or thermally toughened cover glass

Projected capacitive (PCAP) touch with glove and wet-touch support

Optical bonding to eliminate air gaps and reduce internal condensation

UV-stable coatings to prevent yellowing

High-brightness panels (1000+ nits) for outdoor readability

At CDS, our CrystalVUE Industrial Display Range and Custom PCAP Touch Solutions are designed specifically for applications where optical stability must be maintained across extreme temperature swings.

Optical bonding not only improves impact resistance but significantly enhances readability in high-ambient-light conditions — a critical requirement for outdoor and transportation deployments.

Mechanical & Thermal Design for Extreme Conditions

Engineering Touchscreens for Extreme Operating Conditions requires careful mechanical integration.

Key considerations include:

Controlled expansion tolerances between glass, sensor, and frame

Reinforced mounting systems for vibration environments

Gasket and sealing design for IP65/IP67 protection

Passive thermal dissipation via metal backplates

Integration with active heating or cooling where required

For example, CDS’s EmbeddedVUE Panel PC Range supports extended temperature operation and can be configured with conformal coating and industrial-grade components for long-term deployment in demanding applications.

Electrical Design & Signal Integrity

Harsh industrial environments often introduce electrical noise, unstable power supplies, and EMI challenges.

Robust Touchscreens for Extreme Operating Conditions must include:

Industrial-grade power regulation

Shielded display cables

Grounded metal enclosures

EMI filtering

Reliable industrial connectors

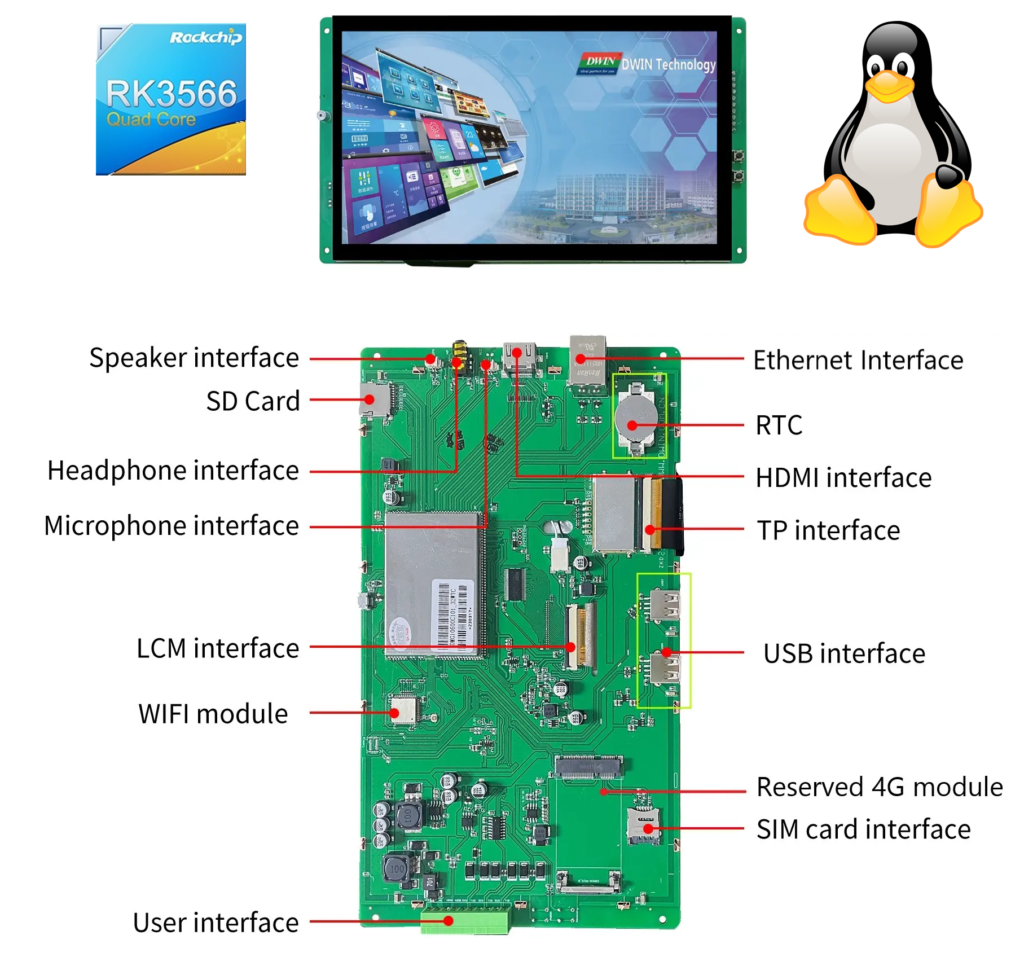

Our DWIN-based industrial display solutions and Linux/Android embedded platforms are designed with electrical resilience in mind, ensuring stable touch performance even in electrically noisy automation environments.

Environmental Testing & Validation

Reliability must be proven — not assumed.

CDS works with partners to validate Touchscreens for Extreme Operating Conditions through:

Thermal shock testing

Extended temperature burn-in

Vibration and shock testing

Humidity and condensation cycling

UV ageing exposure

This ensures consistent optical performance, accurate touch response, and long operational lifecycles.

CDS Solutions for Extreme Temperature & Harsh Environments

Crystal Display Systems offers:

Fully optically bonded assemblies

Conformal-coated PCB assemblies

Whether you require a modified standard unit or a fully bespoke design, CDS engineers support customers from concept through to production.

Why Choose CDS for Touchscreens for Extreme Operating Conditions?

Decades of display integration experience

Customisation capabilities

Industrial and long-lifecycle components

Technical engineering support

UK-based technical consultation

Flexible volume production

Extreme environments demand engineered reliability — and CDS delivers display and touchscreen systems built for performance under pressure.

Engineering Touchscreens for Extreme Operating Conditions requires a complete systems approach — rugged materials, optical bonding, thermal management, and electrical stability all working together.

At Crystal Display Systems, our industrial-grade displays, optically bonded panels, and IP-rated Panel PCs are built to perform reliably in the harshest environments.

For display solutions that won’t fail under pressure, contact CDS today.