Let CDS help you on your route to the ideal embedded solution for you

Industrial Panel PCs have become indispensable tools in various sectors, ranging from manufacturing to healthcare. Their integration of robust computing power with durable design makes them ideal for environments where standard computers would fail. This guide will delve into the key aspects of Industrial Panel PCs, from their essential features to the factors you should consider when purchasing one.

What are Industrial Panel PCs?

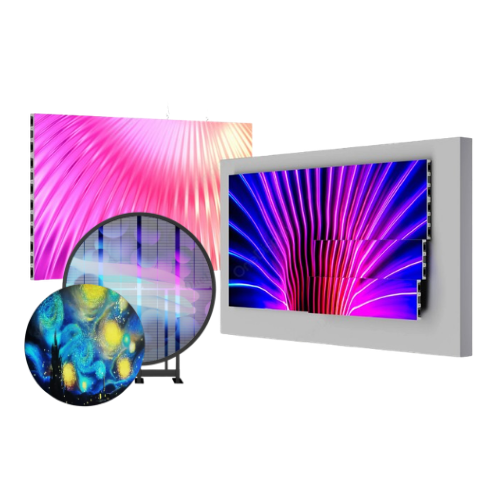

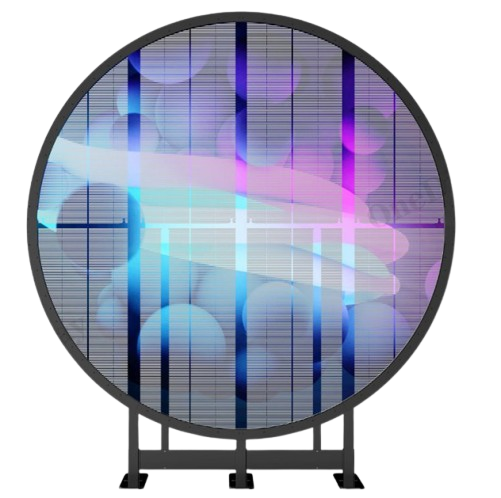

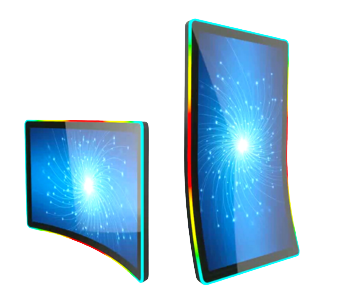

Panel PCs, or Panel Personal Computers, integrate a computer into a flat-screen display, allowing for easy mounting and usage in diverse environments. These devices are specifically engineered to endure harsh industrial conditions.

Typically constructed with stainless steel or other durable materials, they are designed to withstand high-traffic and adverse environments.

Modern Panel PCs offer high-speed computing, visual interface capabilities, and touch display technology, ensuring they are both durable and functional for various industrial applications, from automation to healthcare.

Advantages of Panel PCs in Industrial Applications

Industrial Panel PCs significantly improve productivity and operational efficiency in various sectors. Their robust design and multifunctional capabilities make them ideal for industries such as manufacturing, warehousing, food processing, healthcare, and hospitality. Embracing these advanced computing solutions helps businesses stay competitive in the digital age.

What is an HMI?

HMI, or Human Machine Interface, is any interface that allows humans to interact with machines or their systems. This can be a physical interface, like buttons and lights, or a digital one, such as touchscreens and keyboards. HMIs are crucial for operating and monitoring industrial systems, making them integral components of Industrial Panel PCs.

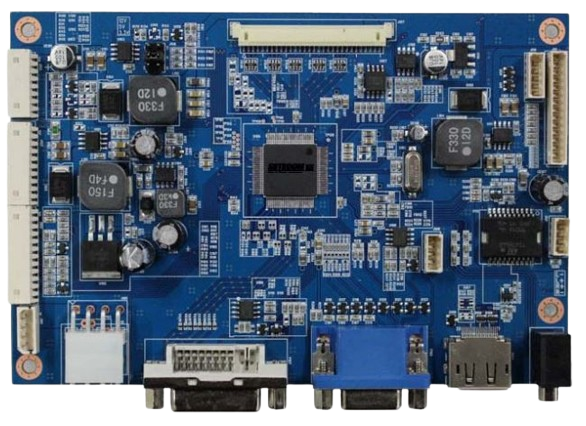

Key Features of Industrial Panel PCs

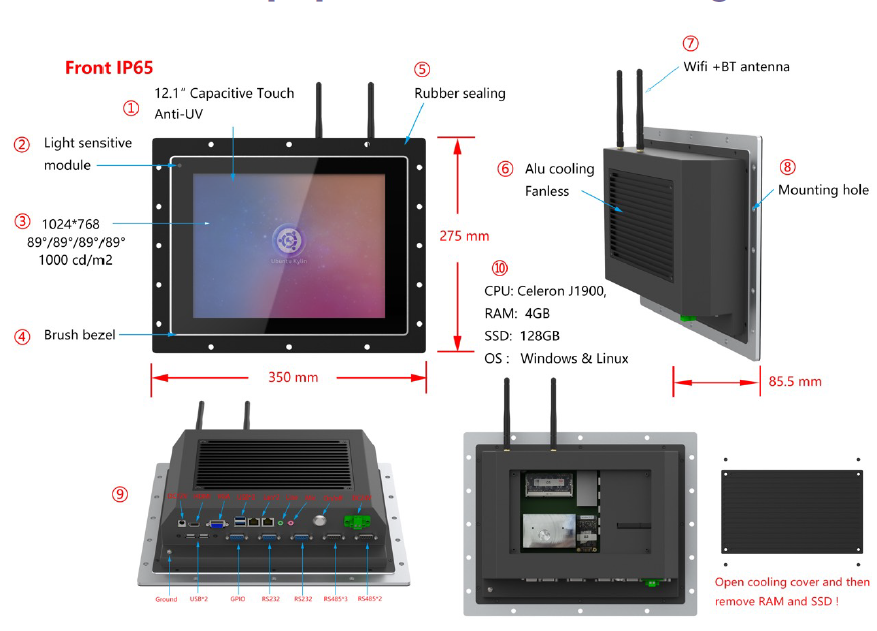

Durability

Industrial Panel PCs are designed to be rugged and long-lasting. They can operate efficiently under extreme conditions, including exposure to shock, vibration, and extreme temperatures. The robust construction ensures they can withstand the demands of volatile industrial environments.

Visibility

High-resolution screens are a hallmark of reliable Panel PCs, providing enhanced visual fidelity. Industrial Panel PCs often use TFT LCD technology, offering aspect ratios like 16:9, which is standard for various high-definition formats. This ensures that the visual output is clear and detailed, crucial for monitoring and control tasks.

Fanless Design

Many Panel PCs utilise a fanless design, employing heatsinks to dissipate heat. This design increases energy efficiency and durability by eliminating the need for ventilation holes, thus protecting the internal components from dust and liquids. The fanless design also enhances the system’s resistance to shock and vibration, contributing to a higher Mean Time Between Failure (MTBF).

Factors to Consider When Buying a Panel PC

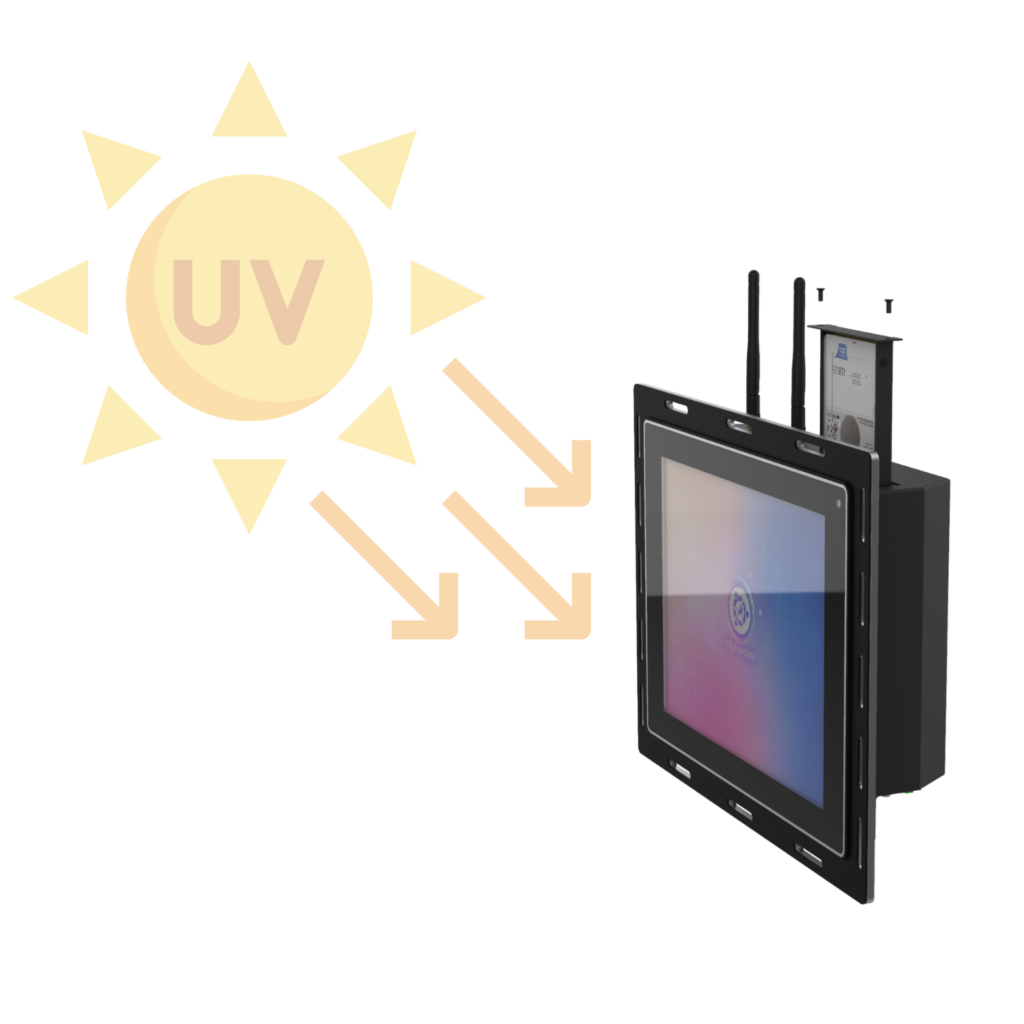

Brightness

Screen brightness is crucial depending on your work environment. For outdoor applications, a screen with high brightness is necessary to combat glare from sunlight. Conversely, for indoor environments, overly bright screens may cause discomfort and should be avoided.

Size

Panel PCs come in various sizes, so it is important to choose one that fits your workspace. Consider both the screen size and the overall dimensions, including weight, to ensure proper installation and usage.

Mounting

Consider the mounting options available for your chosen Panel PC. Common mounting types include VESA mounts, bezel frames for front installation, and rack mounts for server applications. Choose a mounting option that best suits your workspace and application requirements.

What are Industrial Panel PCs used for?

Industrial Panel PCs are primarily used for data acquisition and process control. Their specific functions vary across industries, tailored to meet the unique demands of each sector.

What are the protection standards?

Look for Ingress Protection (IP) ratings when selecting a Panel PC. These ratings indicate the device’s effectiveness in sealing out dust, liquids, and other external materials, ensuring longevity and reliability in harsh environments.

What types of mounting are available?

Common mounting options for Industrial Panel PCs include VESA mounts (stand, arm, or base mounts), bezel frames for front installation, and rack mounts for servers. Choose the mounting type that best fits your installation needs.

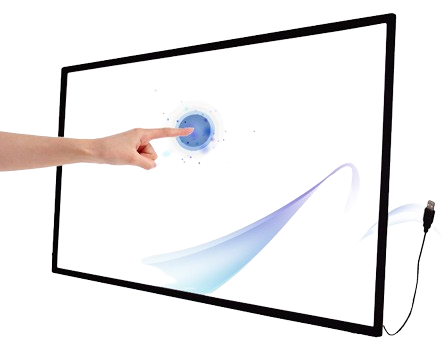

Which touchscreens are best for Panel PCs?

The choice of touchscreen technology depends on the environment and application. Surface Capacitive Touchscreens, common in consumer electronics, require direct skin contact and are not suitable for gloved hands. Resistive Touchscreens, which respond to pressure, can be used with gloves, making them ideal for healthcare, hospitality, and heavy equipment industries.

Industrial Panel PCs are versatile, durable, and essential for modern industrial applications. Understanding their features and the factors to consider when purchasing one can help you choose the right device for your needs. By integrating these advanced systems, businesses can enhance their operational efficiency and stay ahead in the competitive landscape.

If you require further help and assistance with any project, you may have for Panel PCs. Please contact our technical sales team for our full EmbeddedVUE range.