CDS help their customers to work smarter with TFT displays in manufacturing

In today’s fast-paced manufacturing world, efficiency, precision, and visibility are vital for maintaining a competitive edge. At Crystal Display Systems (CDS), we empower factories and production lines with advanced TFT displays in manufacturing and industrial display solutions designed to make operations smarter and more reliable.

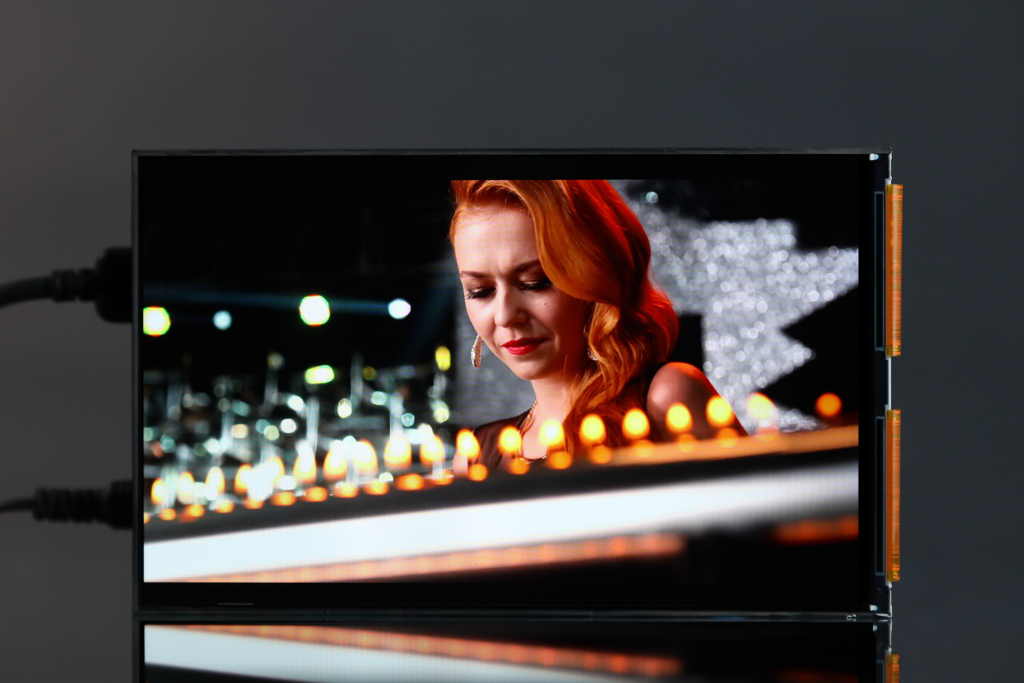

One technology making a major impact in industrial automation is the TFT (Thin-Film Transistor) display. With exceptional clarity, fast refresh rates, and rugged performance, TFT displays are becoming the go-to solution for modern manufacturing environments.

Challenge: Limited Visibility and Outdated Display Systems

A leading automotive components manufacturer was struggling to track real-time production metrics across several assembly lines. Their legacy display systems were slow, prone to overheating, and often failed under intense factory conditions. This lack of visibility led to inefficiencies, increased downtime, and delays in responding to production issues.

Solution: Industrial TFT Displays from Crystal Display Systems

CDS stepped in to deliver a tailored TFT display integration designed for the factory’s demanding environment. The upgrade introduced high-resolution, durable screens capable of delivering crisp, accurate data around the clock — even under heat, vibration, and dust exposure.

Operators could instantly monitor machine status, output counts, and quality metrics in real time, without needing to leave their workstations. This improved situational awareness, reduced human error, and enhanced communication between teams.

Additionally, the new touch-enabled interfaces provided by CDS allowed seamless interaction with factory management software — enabling quick adjustments, data input, and error reporting directly from the production floor.

Results: Improved Productivity and Reduced Downtime

After implementing CDS’s industrial-grade TFT displays, the manufacturer saw immediate improvements in:

Operational visibility – live data at a glance

Decision-making speed – faster responses to issues

Process efficiency – streamlined workflows and reduced bottlenecks

Reliability – consistent performance in challenging conditions

These enhancements contributed to measurable gains in productivity and a significant reduction in production downtime.

Customisation for Every Manufacturing Need

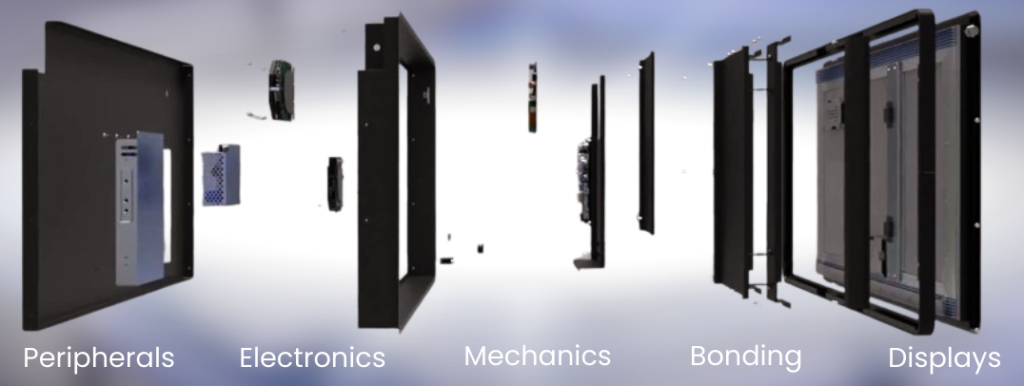

Every manufacturing environment is unique, which is why CDS offers custom TFT display solutions in a range of sizes, interfaces, and configurations. Whether for wall-mounted control panels, embedded workstation monitors, or factory automation systems, CDS designs each display to integrate perfectly within existing infrastructure.

This flexibility ensures manufacturers receive not only a high-performance display but a solution optimised for their exact operational requirements.

This case study highlights how Crystal Display Systems’ TFT displays are helping factories achieve higher efficiency, improved accuracy, and better process control.

By combining rugged industrial design with cutting-edge display performance, CDS enables manufacturers to embrace smarter, data-driven production.

As industries continue to evolve, TFT displays from Crystal Display Systems are proving to be a vital part of the modern manufacturing toolkit.