By: Richard McKay, VP of Sales North America, Crystal Display Systems, Ltd.

In today’s technologically driven world, Liquid Crystal Displays (LCDs) are ubiquitous, playing pivotal roles in various industries. From consumer electronics to medical devices, LCDs are the windows through which we interact with technology. When it comes to choosing the right LCD for your application, understanding the differences between standard and Customised Displays and the value-added services available for your Display of choice can make a significant impact with not only the performance and usability of your product but if done properly can make your product a stunning super star in your market space.

Standard LCDs

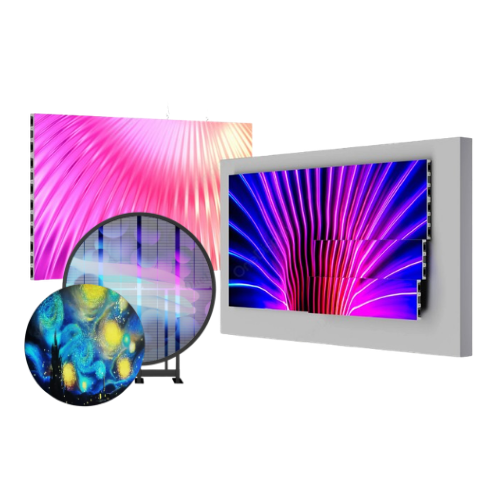

Crystal Display Systems has a massive arsenal of Standard LCDs which are stock manufacturer items in a multitude of sizes, resolutions and shapes. These factory displays are designed to meet many common requirements across a broad range of applications and normal operating environments. These displays are usually stock, have good lifecycles and standardized interfaces making them ideal for general use. These cost-effective, readily available, and easy to integrate panels make them our most popular products. These standard LCDs include Alphanumeric displays, Graphic displays, and Segment displays. These are often used in designs where specific customization is not critical, such as in consumer electronics, industrial equipment, standard medical devices and ioT applications.

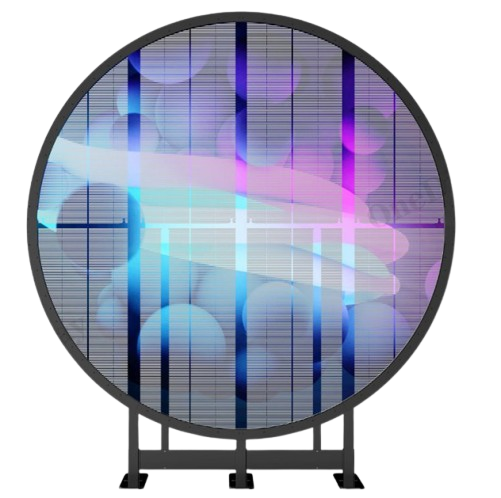

Custom LCDs

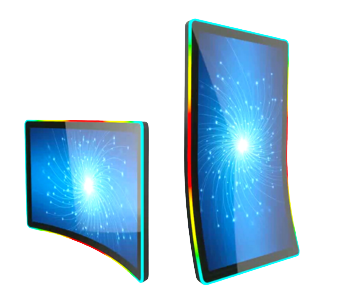

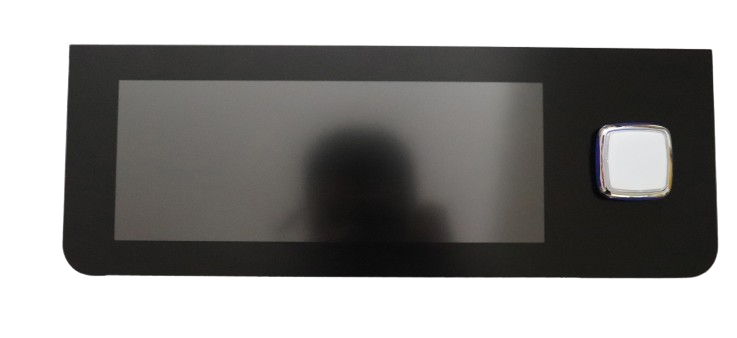

CDS’s Custom LCDs, on the other hand, are tailored to meet the unique needs of specific applications. When standard options do not suffice, custom LCDs provide the flexibility to design a display that aligns perfectly with the desired specifications. Customization can include modifications in size, shape, resolution, backlighting, touch design and capabilities and interface type with pin-mapping matching for drop in EOL replacements. Heavy industrial designs and medical devices, automotive, military and aerospace designs really benefit from our custom display design services.

Value-Added Services

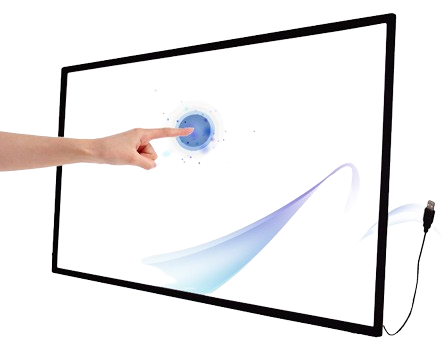

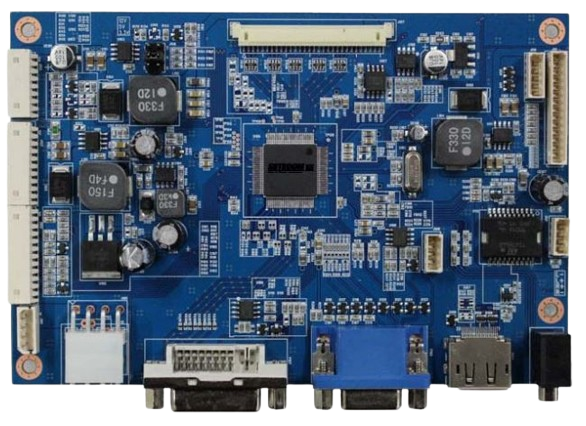

Crystal Display Systems additionally offers best in class Value-Added Services such as Optical Film Enhancements, Customised High-Bright upgrades for high ambient light viewing (Sunlight Readable), Customised Touch designs with specialty cover glass, décor glass and vandal proof glass as well as client logo and silk-screening services. Optical Bonding of multiple types of overlays from touch screens to glass and plastics has become one of our most popular value-add services and one that makes a huge impact on the look of your display at a surprisingly affordable cost. Customised interface cable services are available, customised controller design and kitting programs are created upon request and customised assemblies such as Open Frames and OEM Monitor designs round out our outstanding CDS value services.

Choosing between standard and custom LCDs depends on the specific needs of your application. While standard LCDs offer cost-effective and readily available solutions, custom LCDs provide the flexibility to create unique, high-performance displays. Leveraging value-added services can further enhance the functionality and durability of your LCDs, ensuring that they meet the highest standards of performance and user experience. By understanding these options, you can make informed decisions that best align with your product’s requirements and market goals. Crystal Display Systems is there for you every step of the way. Call us today and let us show you what we can do for you.