Our Commitment to Excellence Starts with our OEM Factory Facilities and Services

At CDS, we take immense pride in delivering high-quality products and services to our customers, beginning with our Factory Facilities and Services. This commitment to excellence is reflected in the state-of-the-art facilities and advanced processes we employ in our manufacturing operations. Our dedication to maintaining the highest standards is evident in our certifications, technology, and stringent quality controls. Here, we provide an inside look at some of the key facilities and services that make CDS a leader in the industry.

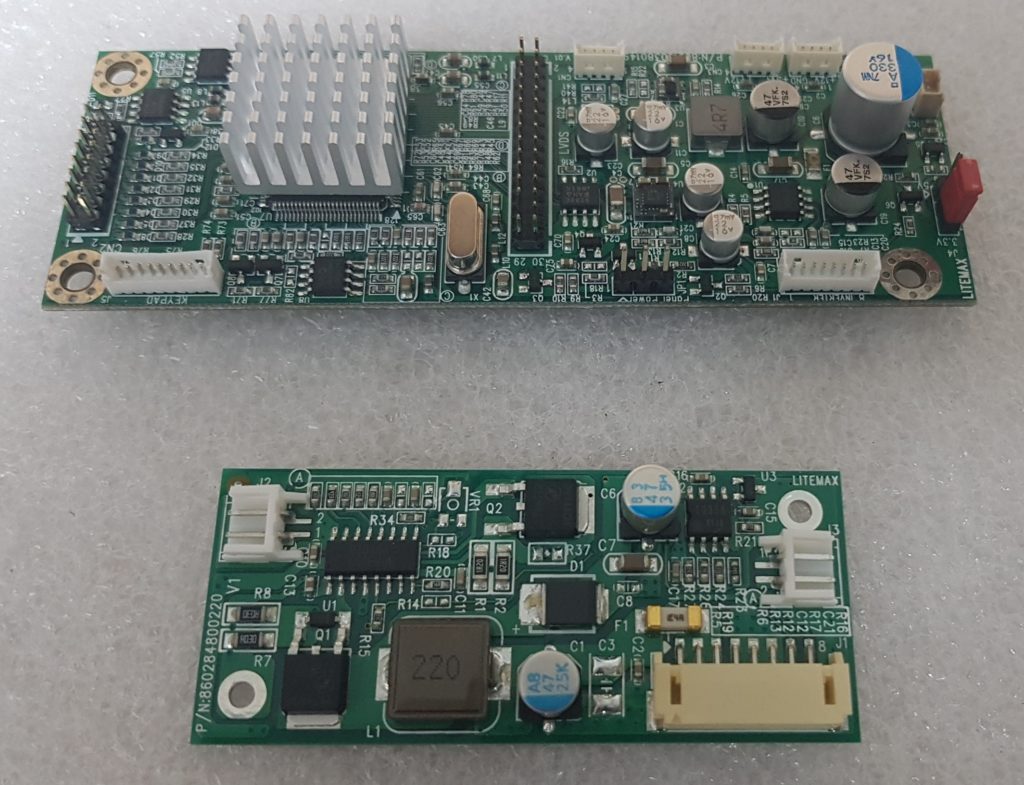

IPC-A-610 Certification: Ensuring Excellence in Electronics Assembly

One of the cornerstones of our production process is our adherence to IPC-A-610 standards. This certification is the industry standard for the acceptability of electronic assemblies, and it guarantees that every product leaving our facility meets the highest quality requirements. Our teams are thoroughly trained and regularly audited to ensure they meet these exacting standards, ensuring that our customers receive reliable and durable products every time.

IATF 16949: Commitment to Automotive Quality

Our commitment to quality extends to the automotive sector, where we hold the prestigious IATF 16949 certification. This globally recognised standard ensures that our processes meet the rigorous demands of the automotive industry. From design and development to production and delivery, our IATF 16949 certification reflects our dedication to continuous improvement, defect prevention, and reducing variation and waste in the supply chain. This certification is a testament to our ability to deliver products that meet the stringent requirements of automotive customers worldwide.

Cutting-Edge COG – Inline & Offline Flexibility

At CDS, we understand the importance of flexibility in manufacturing. Our Chip-on-Glass (COG) technology offers both inline and offline production capabilities, allowing us to cater to diverse customer needs efficiently. Whether it’s a small batch or a large-scale production run, our COG processes are designed to deliver exceptional quality with remarkable flexibility. This versatility ensures that we can meet tight deadlines while maintaining the highest standards of precision.

ESD Protection and Access Control: Safeguarding Quality

Electrostatic Discharge (ESD) can be a significant threat to sensitive electronic components. That’s why our facilities are equipped with advanced ESD protection and stringent access control measures. We maintain controlled environments to prevent any potential damage from static electricity, ensuring the integrity of our products throughout the manufacturing process. Our rigorous access control protocols also ensure that only authorised personnel can enter sensitive areas, further safeguarding the quality of our work.

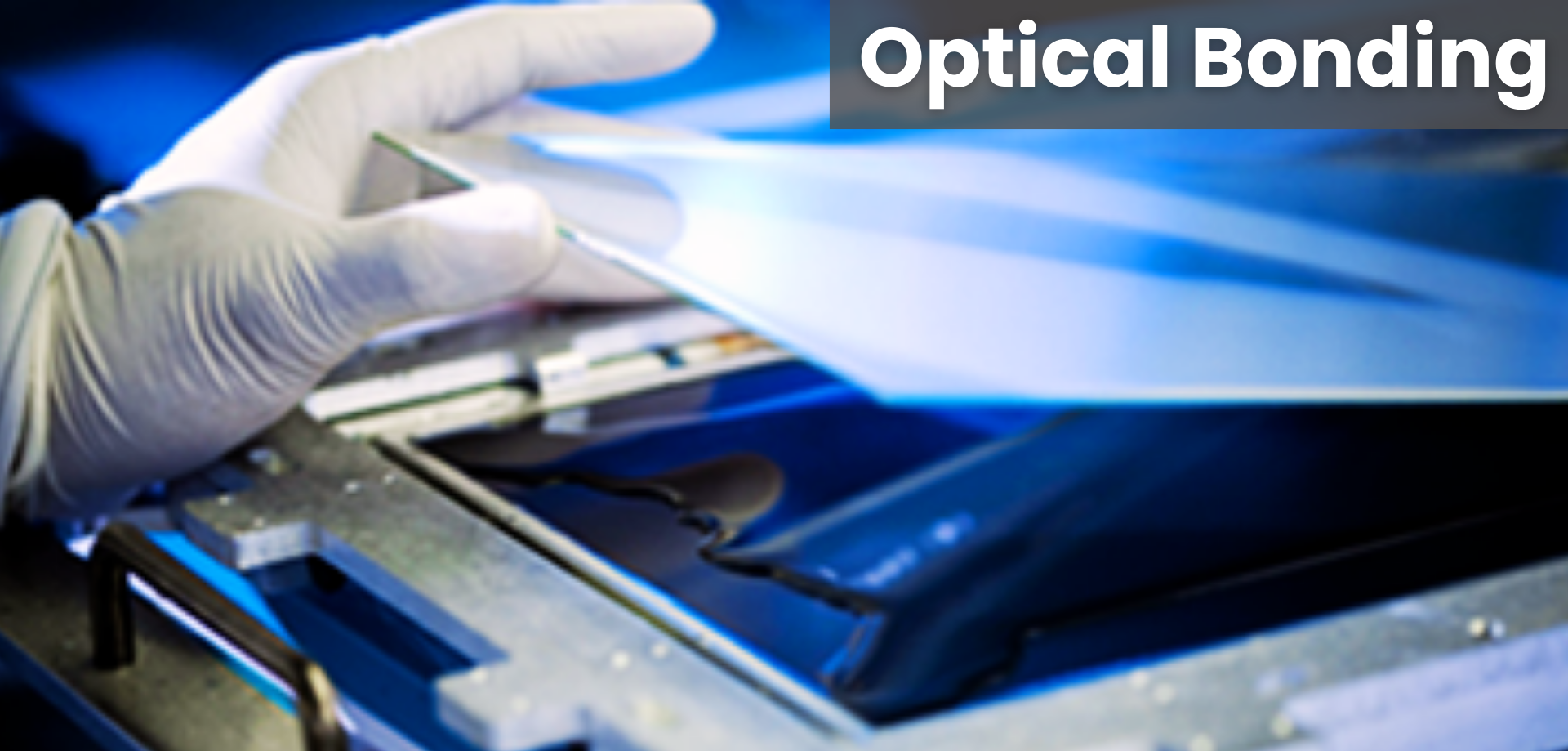

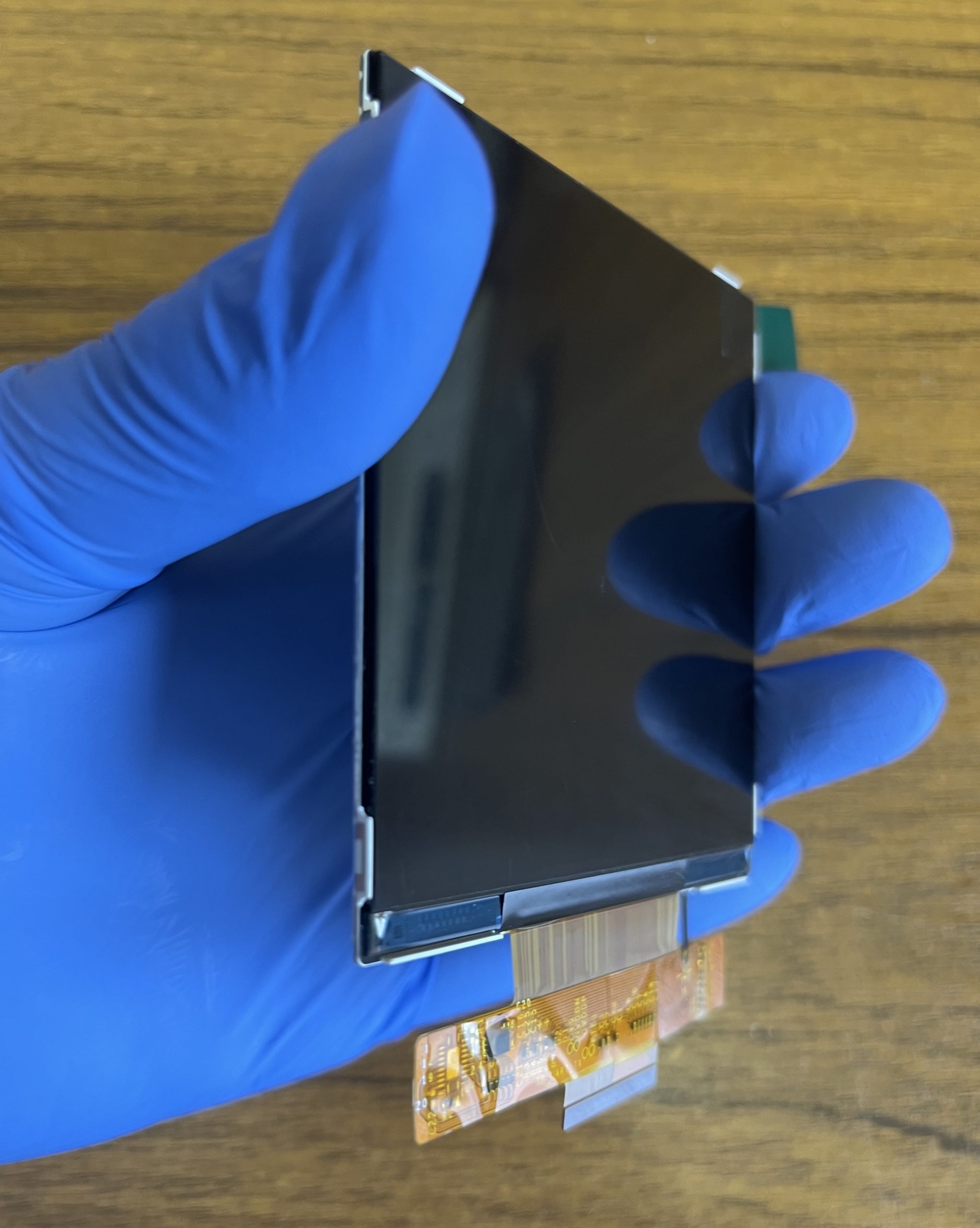

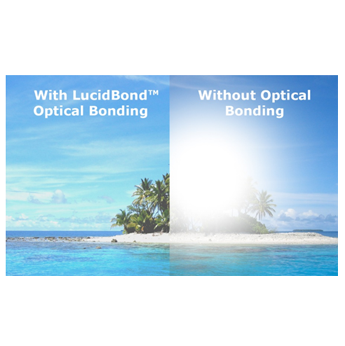

Advanced Optical Bonding Facilities: OCR/OCA

Our optical bonding facilities are equipped with the latest technology, including Optical Clear Resin (OCR) and Optical Clear Adhesive (OCA) processes. These methods enhance the durability and visual clarity of display screens by reducing reflections, improving contrast, and increasing overall robustness. Whether it’s for consumer electronics, automotive displays, or industrial applications, our optical bonding services are designed to meet the most demanding specifications, ensuring that our customers receive the best possible product.

Conformal Coating: Protecting Your Investment

To further enhance the reliability and longevity of our electronic assemblies, we offer conformal coating services. This protective coating shields electronic circuits from harsh environmental conditions such as moisture, dust, and chemical contaminants. Our conformal coating process ensures that your products are protected against the elements, extending their lifespan and reducing the likelihood of failure in the field. This service is particularly beneficial for products used in challenging environments, where reliability is critical.

Reliability Testing Equipment: Guaranteeing Performance

At CDS, we don’t just promise quality—we guarantee it through rigorous testing. Our reliability testing equipment is among the best in the industry, allowing us to simulate a wide range of conditions and stress factors. From thermal cycling and vibration testing to humidity exposure and beyond, our testing facilities ensure that every product we manufacture can withstand the rigours of real-world use. This commitment to thorough testing ensures that our customers receive products that not only meet but exceed their expectations.

At CDS, our facilities and services are designed with one goal in mind: to deliver the highest quality products to our customers. From our adherence to global standards like IPC-A-610 and IATF 16949 to our advanced manufacturing processes such as COG flexibility, optical bonding, and conformal coating, we are committed to excellence at every stage. Our investment in cutting-edge technology and rigorous testing further underscores our dedication to providing reliable, durable products. By continuously striving to improve and innovate, we ensure that our customers receive nothing but the best.