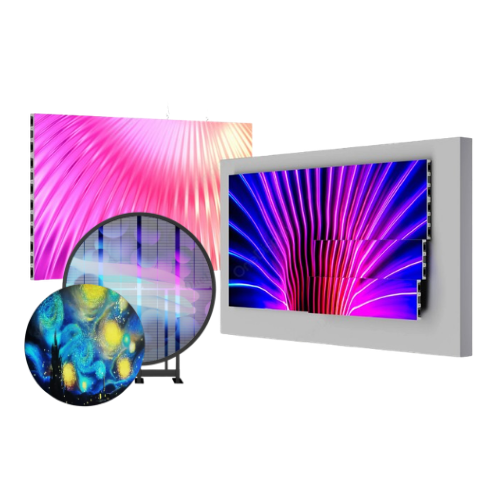

No Matter the Application, the HMI Serves a critical purpose in all projects

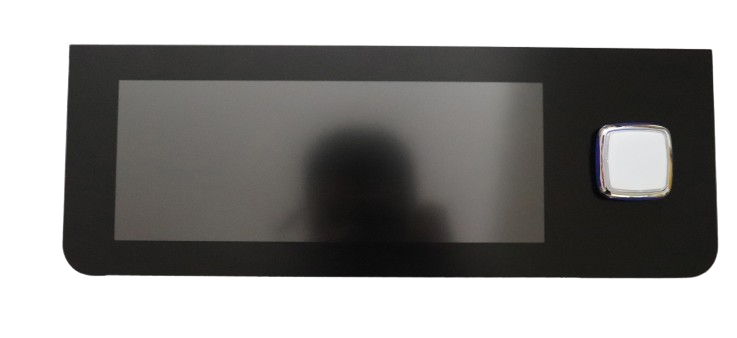

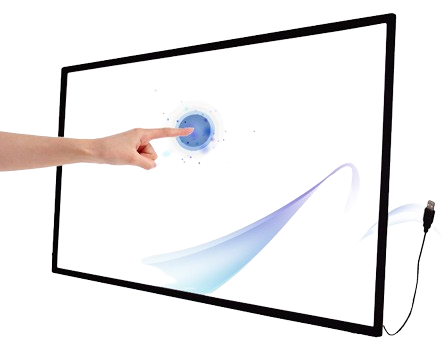

For original equipment manufacturers (OEMs), the human-machine interface (HMI) is a vital component, enabling users to effectively interact with and control devices and systems. Whether it’s an industrial control panel, medical diagnostic equipment, or a self-service kiosk, the HMI serves as the critical link between the user and the underlying technology.

However, the design and integration of a robust HMI system can be far more complex than many OEMs initially anticipate. Numerous factors such as operating systems, environmental conditions, and processing requirements must be meticulously considered from the outset. Failing to address these variables early in the design process can lead to costly redesigns or subpar solutions later on.

The Dangers of a Consumer-Centric Approach

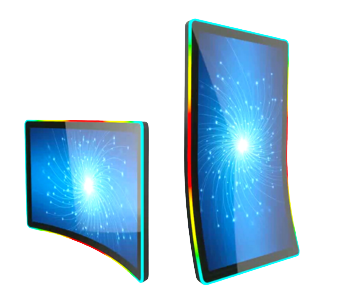

One of the biggest challenges for OEMs is the tendency to approach HMI design with a consumer-product mindset. In a world dominated by sleek smartphones and tablets, it’s easy for developers to assume that these high-resolution displays can be seamlessly applied to industrial or specialised applications.

While consumer-grade displays may serve as an initial proof of concept, they are not designed to withstand the long-term reliability, environmental resilience, or rigorous demands of industrial, medical, or automotive applications. Relying on them in OEM product lines can lead to significant and avoidable challenges.

Considerations for Temperature Tolerance, Lifespan, and More

It is not possible to design around commercial-grade products, those who do end up in scenarios that often lead to extensive rework. In extreme cases, OEMs have had to redesign entire product housings at significant cost due to unforeseen HMI component issues like availability and supply.

Moreover, the longevity and maintenance aspects of consumer products pose additional challenges. Consumer-grade components quickly become obsolete, forcing OEMs to continually requalify new components, which can undermine product certification and increase total cost of ownership (TCO).

Prioritising Application-Specific Requirements

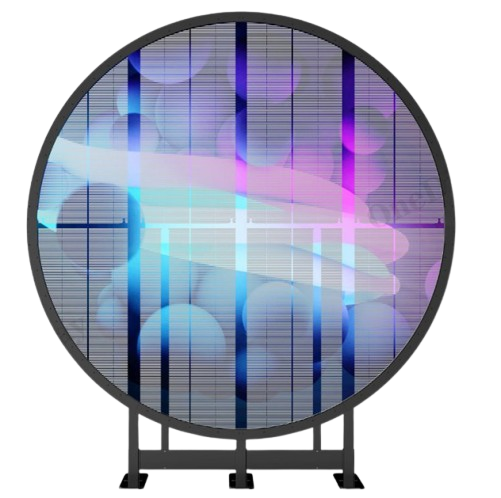

It’s clear that a consumer-oriented approach to HMI integration is fraught with risks. Costly rework, delayed time-to-market, and suboptimal performance are likely outcomes. Instead, OEMs should prioritise application-specific requirements from the outset and select components that meet these criteria. Factors such as operating temperatures, shock and vibration tolerance, optical treatments, and ingress protection ratings should drive hardware selection. This application-focused mindset is crucial, even in seemingly straightforward cases.

Expertise-Driven HMI Development

Given the complexities involved, OEMs benefit significantly from involving an experienced HMI integration partner like CDS early in the design process. With a broad range of expertise, CDS can assess each application holistically and anticipate potential issues before they arise.

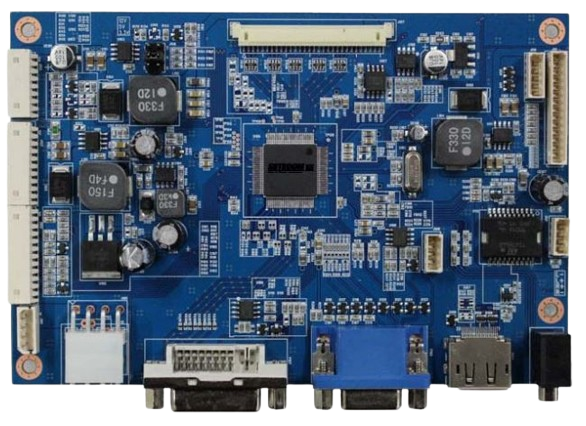

Additionally, CDS’s extensive portfolio of industrial-grade components, sourced from reputable suppliers with decades of manufacturing experience, allows them to craft highly optimised solutions. These solutions align with the client’s exact needs in terms of processing power, temperature ratings, ruggedisation, and longevity.

Beyond individual components, solution providers offer significant value through deep integration expertise gained from numerous client projects. Their engineers can advise OEMs on smart design choices, such as passive cooling, peripheral integration, and connectivity options, to ensure a seamless HMI integration.

Crucially, experienced HMI partners can help OEMs accurately assess the TCO of their solutions. While industrial-grade components may come with a higher upfront cost, the long-term savings in reduced maintenance, qualification costs, and rework can be substantial.

An optimised HMI setup is far more than just a user-facing screen or control interface. By prioritising HMI development early and involving experienced partners, OEMs can also streamline their backend systems, including software, communications, and overall system architecture.

In a wide range of applications—from industrial machinery and medical devices to PoS units, public information displays, parking meters, and coffee machines—the HMI represents the critical point where human interaction meets machine functionality. Investing in the proper HMI integration lays the foundation for an intuitive, reliable user experience, backed by a robust and future-proof product architecture.

By adopting a thoughtful, expertise-driven approach from the beginning, OEMs can avoid the common pitfalls and costly reworks that frequently hamper HMI integration. With the right partner involved from the early stages, the path is clear for smooth design cycles, faster time-to-market, compliance assurance, and long-term success for next-generation HMI-enabled products.