+44 (0)1634 791600

info@crystal-display.com

Newsletter Sign Up!

+44 (0)1634 791600

info@crystal-display.com

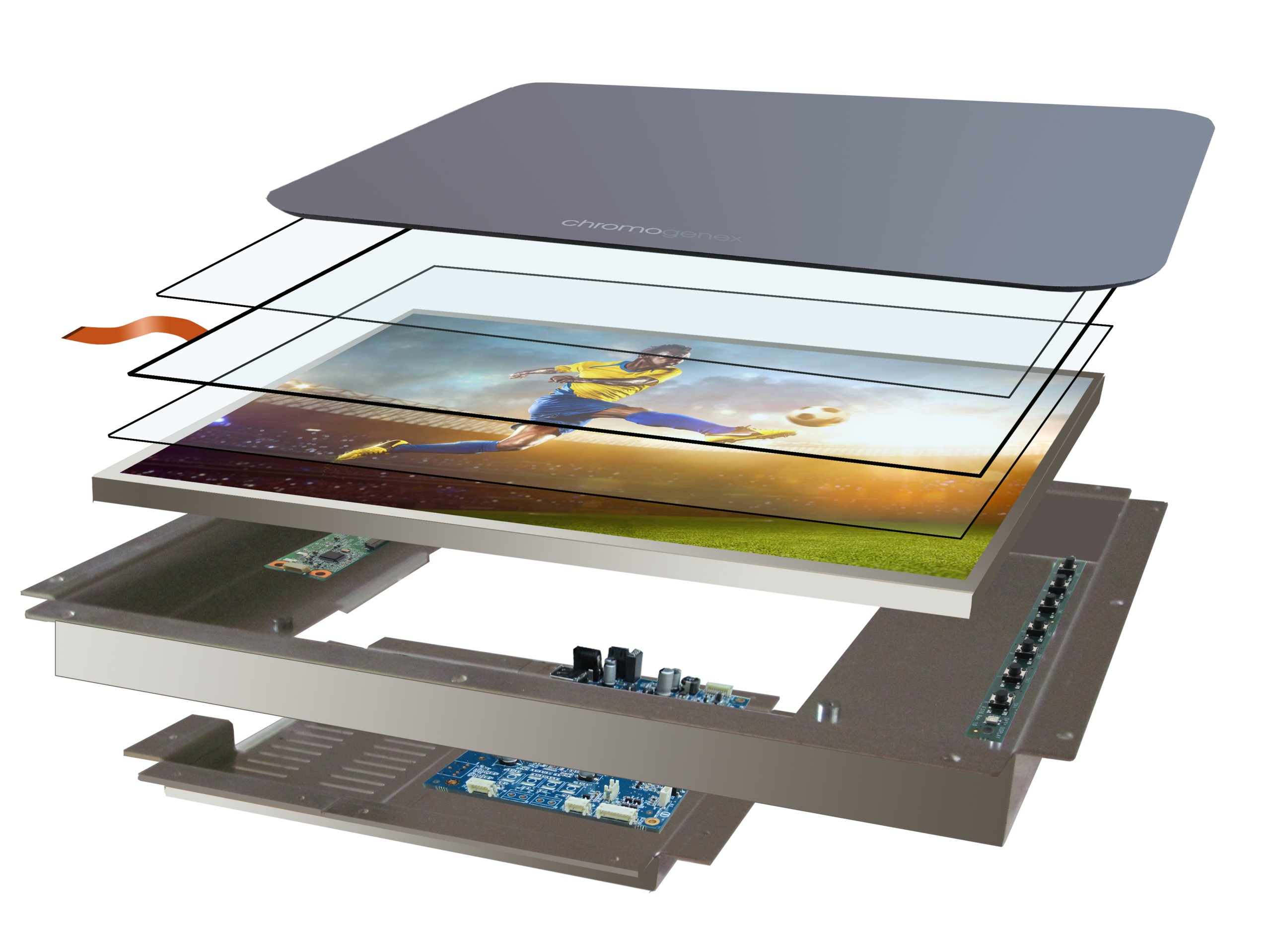

Crystal Display Systems Ltd has strengthened its optical bonding services through a strategic partnership with CiVUE, a leader in Optical Bonding (OB). This collaboration underscores their shared commitment to promoting optical bonding as a superior alternative to traditional air gap ‘strip’ bonding for industrial applications requiring protective cover glass or touchscreens.

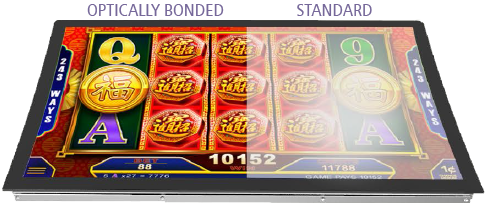

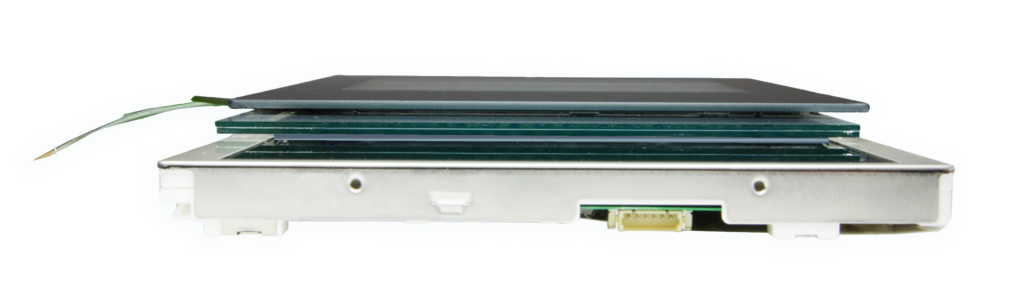

Optical bonding improves both optical performance and durability by directly adhering the cover glass or touchscreen to the display, eliminating air gaps. This reduces reflections, enhances contrast and brightness, and improves readability—especially in bright sunlight or high ambient light.

CiVUE’s proprietary materials and reworkable process deliver advanced, cost-effective solutions like LucidBond™ and ArmorBond™, ensuring sunlight readability, UV protection, and enhanced vandal resistance for outdoor displays and portable devices.

By securely attaching a cover lens, such as anti-reflective glass or a touch panel, CiVUE Optical Bonding Technology minimizes reflectance to as low as 0.2%*, significantly boosting contrast in high-light environments. Additionally, it enhances impact absorption and UV protection, extending the display’s lifespan even in extreme conditions.

*Reflection rates and contrast ratios may vary based on layer properties.

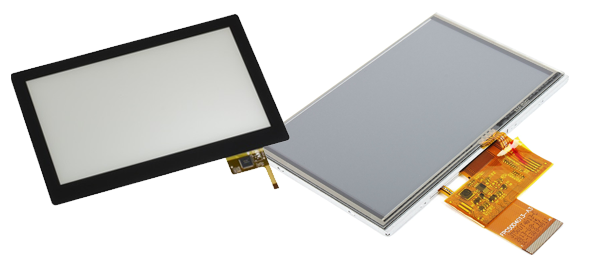

Optical bonding is a process used in display technology to enhance the performance and durability of screens, particularly in outdoor or harsh environments. It involves attaching a protective cover glass or touchscreen directly onto the display panel using an adhesive.

This eliminates the air gap between the layers, reducing reflections and improving contrast, brightness, and readability, especially in bright sunlight or high ambient light conditions.

Additionally, optical bonding enhances the display’s resistance to moisture, dust, and other environmental factors, making it suitable for rugged applications such as industrial equipment, outdoor signage, and military displays.

Improved Optical Clarity: Optical bonding minimizes reflections by eliminating the air gap between the display panel and the protective cover glass or touchscreen. This results in enhanced contrast, brightness, and overall optical clarity, making the display easier to read in various lighting conditions.

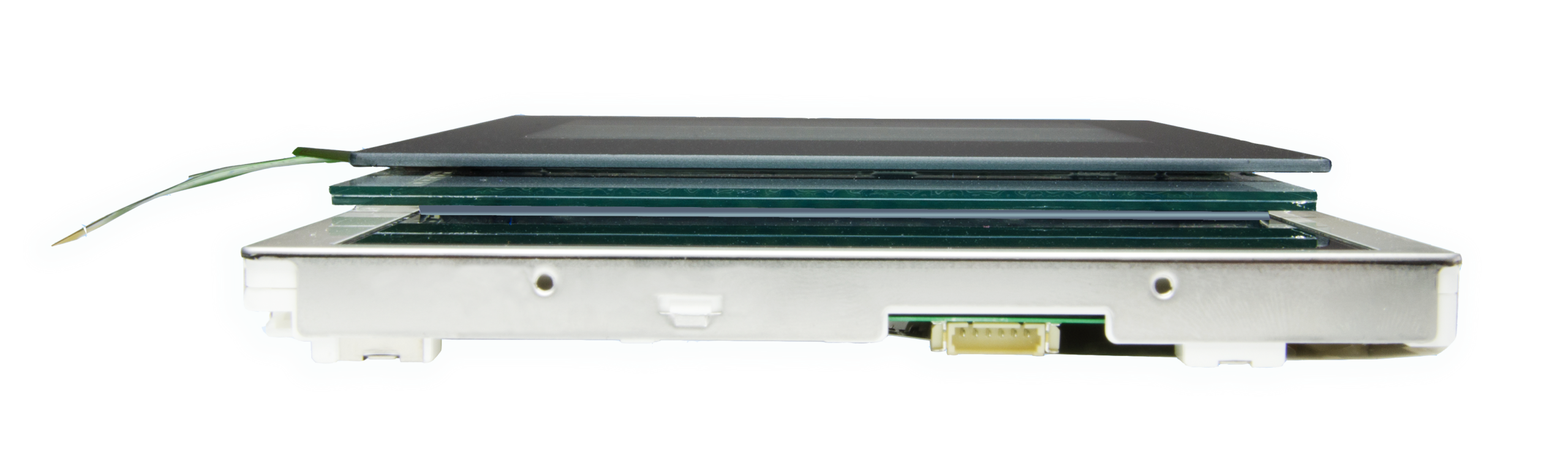

Enhanced Durability: By securely bonding the layers together, optical bonding increases the display’s resistance to moisture, dust, and other environmental factors. This makes it suitable for rugged applications and extends the lifespan of the display, reducing maintenance costs.

Reduced Glare and Reflections: The absence of an air gap reduces internal reflections within the display, resulting in reduced glare and reflections on the screen surface. This improves visibility and readability, particularly in outdoor or high ambient light environments.

Improved Touch Performance: Optical bonding enhances the responsiveness and accuracy of touchscreens by reducing the distance between the touch sensor and the display panel. This results in a more precise and consistent touch experience, even at the edges of the screen.

Increased Impact Resistance: The bonded structure adds an additional layer of protection to the display, making it more resistant to impacts and scratches. This is particularly beneficial in industrial environments where displays may be subjected to rough handling or accidental impacts.

Wide Temperature Range: Optical bonding improves the thermal stability of the display, allowing it to operate reliably across a wide temperature range. This makes it suitable for use in extreme temperatures, such as in outdoor or automotive applications.

Customization Options: Optical bonding can be tailored to meet specific design requirements, including various types of cover glass, adhesives, and bonding techniques. This allows for flexibility in designing displays that meet the needs of different industries and applications.

Anti-Newton Ring Effect: Optical bonding helps to mitigate the occurrence of Newton rings, which are undesirable interference patterns that can appear between the layers of a display. By securely bonding the layers together, optical bonding reduces the likelihood of Newton rings, ensuring a clear and uniform visual experience without distracting artifacts or distortions.

By reducing internal reflections between the layers of the display, optical bonding enhances screen clarity and visibility, especially in bright or outdoor environments. This leads to better readability of content and graphics.

The bonding process creates a robust bond between the layers of the display, making it more resistant to shock, vibration, and mechanical stress. This increases the overall durability of the display, making it suitable for use in rugged environments.

Optical bonding minimizes the amount of light that is reflected off the surface of the display, resulting in reduced glare and reflections. This improves viewing angles and provides a more comfortable viewing experience, particularly in high-light environments.

Industrial Displays: Optical bonding improves the visibility and durability of displays used in industrial settings such as control panels, machinery interfaces, and ruggedized devices. It enhances readability in bright environments and protects against dust, moisture, and vibration.

Military and Aerospace: In military and aerospace applications, displays often face harsh environmental conditions. Optical bonding increases display ruggedness, improves readability in sunlight, and enhances resistance to shock and vibration.

Medical Devices: Medical equipment often requires clear, high-resolution displays for monitoring patient data and performing procedures. Optical bonding enhances display clarity, reduces reflections, and makes screens easier to clean, making it ideal for medical monitors, diagnostic equipment, and surgical displays.

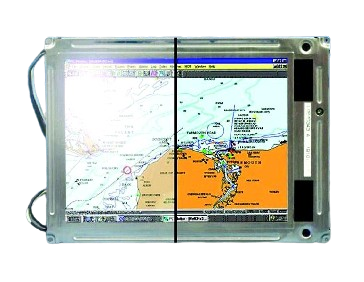

Marine Navigation: Displays used in marine navigation systems must withstand exposure to saltwater, sunlight, and extreme temperatures. Optical bonding improves screen durability, reduces glare, and enhances visibility, making it suitable for marine GPS systems, fishfinders, and radar displays.

Automotive Infotainment: In-car displays face challenges such as glare from sunlight and temperature variations. Optical bonding improves screen readability, reduces reflections, and enhances touchscreen responsiveness in automotive infotainment systems, navigation displays, and rear-seat entertainment systems.

Outdoor Digital Signage: Outdoor digital signage requires displays that can withstand exposure to sunlight, moisture, and temperature fluctuations. Optical bonding improves screen visibility, reduces glare, and enhances durability, making it suitable for outdoor advertising displays, interactive kiosks, and information panels.

Aviation Cockpits: Cockpit displays in aircraft need to provide clear, reliable information to pilots under varying lighting conditions. Optical bonding improves display readability, reduces reflections, and enhances durability, making it essential for avionics displays, flight instruments, and cockpit avionics.

Consumer Electronics: Optical bonding is also used in consumer electronics such as smartphones, tablets, and laptops to improve display clarity, reduce reflections, and enhance touchscreen sensitivity. It provides a more immersive viewing experience and makes devices more durable.