+44 (0)1634 791600

info@crystal-display.com

Newsletter Sign Up!

+44 (0)1634 791600

info@crystal-display.com

Even though mobile devices are becoming more and more capable, they still have a number of key limitations. These limitations restrict their usefulness to businesses aiming to provide maximum customer service at minimal cost. Instead, the implementation of interactive kiosk displays is increasing to allow customers to serve themselves as much as reasonably possible, thereby freeing up human staff without any reduction in customer satisfaction.

It is very easy to assume that the display and touch element is a simple desktop monitor with a touchscreen. However, there are many more factors that should be considered to ensure a quality product that looks good and is reliable. Some of the considerations are – who will be using it, where will it be used, will it be used in direct sunlight, what is the support structure, what is the expected life of the kiosk. All these factors will have an influence over the design and components used. There is little point in having a kiosk in direct sunlight where the user has to shroud their arm around the display to read the information, or if the user can’t use the screen because it is ‘out of order’. It is these considerations which make a good or bad kiosk.

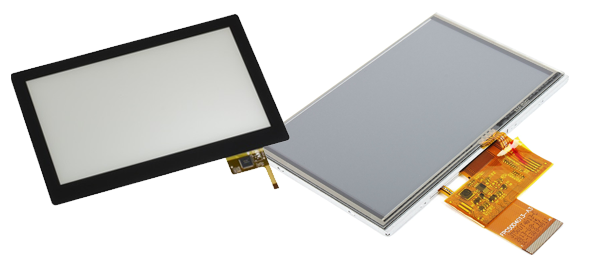

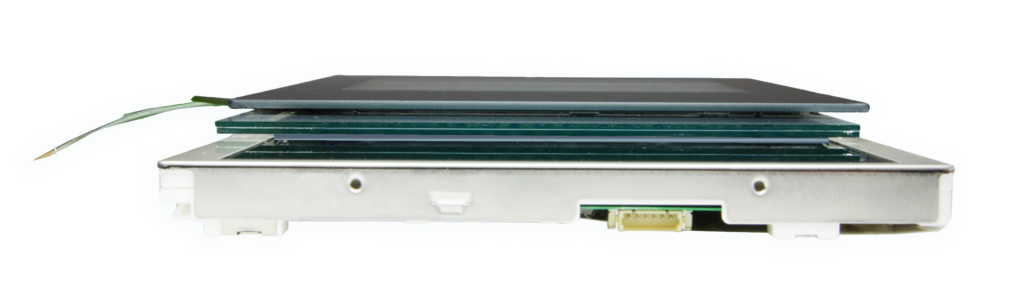

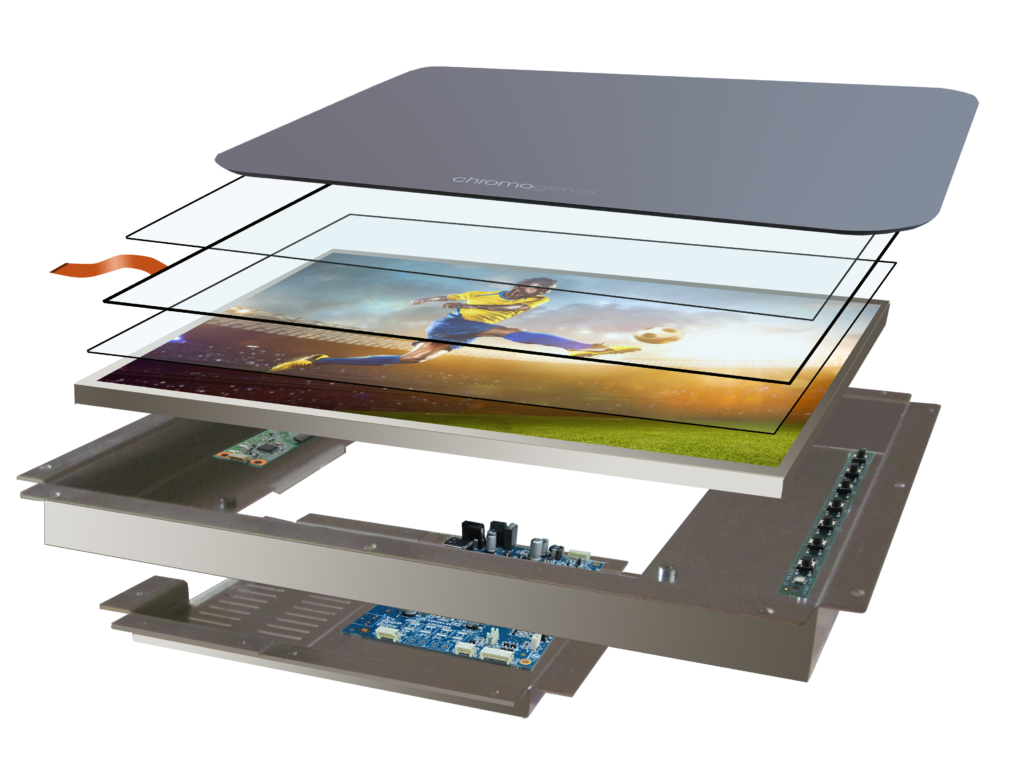

The basic idea behind optical bonding is that an optical grade is used to seal the gap between the cover glass and the actual display. There are various options available, but by far the most common is silicone, which is non-reactive and can withstand moisture. This is usually enhanced by an anti-reflective coating or Antiglare surface finish. Optical bonding can eliminate all the issues currently associated with interactive display kiosks making them both more robust and more effective, giving users a much more enjoyable experience when using them.

The extra solidity makes it much harder for the display to be damaged by rough use. In simple terms, instead of people touching a pane of glass which only has air behind it, they touch a pane of glass which has a solid (albeit invisible) barrier behind it, making the display far more robust.

Visibility is also noticeably improved though optical bonding. Optical bonding on its own goes a long way to reducing internal reflections and if an anti-reflective coating is used as well, then the perceived quality of the display can be increased significantly. In simple terms, the big problem with reflections is that they reduce contrast and contrast is essential to legibility, that’s why most printing is black on white rather than, say, light cream on white. Hence, anything which improves contrast, automatically improves visibility.

The problem of parallax is immediately resolved, which is particularly beneficial for touchscreens as it immediately becomes much easier for users to enter commands accurately. This results in a much better experience for them and fewer calls to staff for additional support or customer service requests.

Optical bonding on its own goes a long way to reducing reflections and if an anti-reflective coating is used as well, then the perceived quality of the display can be increased significantly. In simple terms, the big problem with reflections is that they reduce contrast and contrast is essential to legibility, that’s why most printing is black on white rather than, say, light cream on white. Hence, anything which improves contrast, automatically improves visibility.

Optical bonding strengthens interactive kiosk displays against the effects of environmental pollutants. Hard substances such as dirt and dust have to penetrate not only the outer glass but also the inner sealant. Even corrosive liquids (which in this context includes many common soft drinks) have far less chance of causing serious damage, particularly if spills are dealt with quickly.

Eliminating the pocket of air between the covering glass and the actual display means that fogging and condensation ceases to be an issue as there is no longer any way for the damp air to enter the interactive kiosk display unit.

Once an interactive kiosk display has been successfully installed, the next challenge is keeping it in one piece. Many interactive kiosk displays are designed for use by members of the public, some of whom can be quite heavy-handed and, of course, you cannot risk the glass breaking and injuring them. Even if the interactive kiosk display is intended for use only by internal employees, whom, in principle, can be trained, employers have a duty of care towards them, which means the interactive display kiosk needs to be appropriately robust.

It is critical to ensure the screen is readable, looks good and operates well. Ambient light, be it sunlight or artificial light, can reflect on the screen, also making it harder to read. Displays are notorious for wash out in high ambient light conditions. This effect is where the contrast reduces dramatically through front surface reflection and internal light refraction. In some environments, you may be able to limit the extent, but it is much better using the correct components and construction in the initial design. There is no point in having a kiosk in direct sunlight where the user must shroud their arm around the display to read the information or if the touchscreen response is slow.

Interactive display kiosks have numerous uses in many different contexts. Popular applications include self-service check-ins (and check-outs), catalogue-ordering system, information points, interactive street furniture and wayfinder’s both for the public and for members of a particular organisation. The use of optical bonding reduces or removes the barriers to the deployment of these very cost-effective devices and creates a significantly improved user experience.