CDS putting Transportation Safety and Standards First

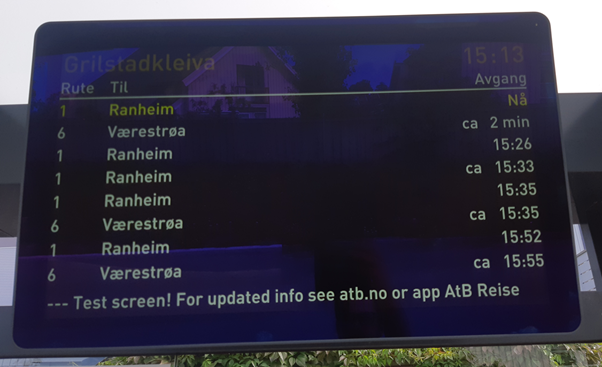

Transportation systems, particularly rail applications, operate in some of the most challenging environments, requiring uncompromising reliability and stringent safety standards. Industrial devices, especially those used in rolling stock, must withstand extreme conditions while maintaining consistent performance for up to 250,000 hours—equivalent to nearly 30 years of continuous operation.

The demands of rail systems are further intensified by limited space, where devices are often installed in close proximity. As a result, these units must function without interfering with one another, adhering to the highest transportation safety and compatibility standards.

Key Challenges in Rail Applications

Environmental Extremes

Rail devices must endure a variety of harsh environmental conditions, from extreme temperatures to continuous vibrations and shocks. These challenges require specialized designs that prioritize resilience and performance.

Moving Applications

The mobility of rolling stock introduces additional complexities, including the need for devices to remain operational under dynamic conditions. Ensuring seamless operation in these environments demands adherence to globally recognized standards, such as EN50155 and IEC 61850.

Core EN50155 Compliance Requirements

With extensive experience in railcar applications, we understand the importance of compliance with the EN50155 standard, which outlines essential requirements for electronic equipment in rolling stock environments. Here are the five key aspects of EN50155 compliance:

- Power Supply Efficiency and Temperature Management

Devices must operate with an efficiency of 85% or higher, supporting a wide range of input voltages and load variations. Temperature monitoring is crucial, especially for rail applications in regions with extreme climate variations.

- Shock and Vibration Resistance

Equipment must withstand significant shocks and vibrations, depending on its mounting position:

- Axle-mounted: Up to 30g shock for 5 hours and 1km/s vibration.

- Body-mounted: Less than 1g vibration and 5g shock.

- Power Supply Input Voltage

EN50155 mandates specific DC input voltage ranges, including 24V, 48V, 72V, 96V, and 110V. Implementing an input capacitor further stabilizes DC input by smoothing out surge currents.

- Efficiency and Reliability

Safety and quality are paramount. EN50155 requires protection against electrical faults, robust wiring and layout, and the use of high-quality connectors. These elements ensure reliability in critical operations.

- Approval Testing

Compliance testing covers a wide range of performance factors, including:

- Visual inspection

- Operation under extreme temperature conditions

- Dry heat testing

- Input voltage range performance

- Surge protection

- Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI) testing

This rigorous process ensures that devices meet operational, safety, and compatibility standards before deployment.

Comprehensive Safety Standards

In addition to EN50155, our products meet other critical safety and performance certifications:

- CE, FCC Compliance: Ensures equipment safety and electromagnetic compatibility.

- Full IP65-Rated: Protection against dust and water ingress.

- IEC 61850 Compliance: This standard ensures redundancy and reliability in power supply systems, critical for electricity transmission and industrial applications.

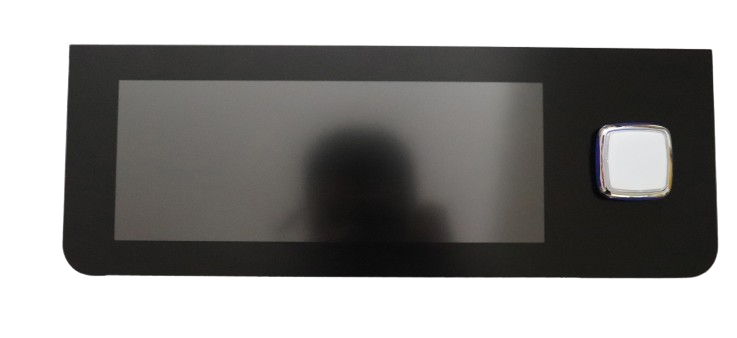

Advanced EMC and EMI Solutions

At Crystal Display Systems, we have invested heavily in mitigating Electromagnetic Interference (EMI) and ensuring Electromagnetic Compatibility (EMC) in our All-in-One Panel PCs. Our industrial automation solutions are designed to meet IEC 61850 standards, addressing customer demands for safe and reliable operations.

Key benefits of our EMC solutions include:

- Radiation Protection: Minimizing electromagnetic interference with other systems.

- Health Safety: Reducing the impact of electromagnetic waves on human health.

- System Reliability: Ensuring seamless operation of HMI automation systems, even in environments with high electromagnetic activity.

By leveraging years of expertise and innovative processes, we provide robust HMI solutions that operate without interfering with other nearby systems—ensuring safety and performance in every deployment.

Meeting transportation safety and performance standards is not just a requirement—it’s a commitment to excellence. At Crystal Display Systems, we are proud to deliver solutions that exceed expectations, combining rugged design, innovative technology, and compliance with global standards like EN50155 and IEC 61850.

Whether for rail, industrial automation, or power systems, our products are built to thrive in the most demanding environments, ensuring the safety, reliability, and efficiency that modern transportation systems demand.

For more information about our solutions, or to find out how we can support your specific application, contact us today.