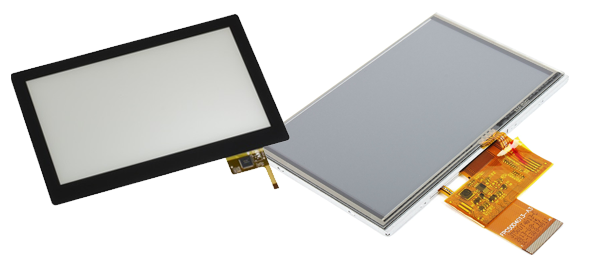

Optical bonding is a process by which a substrate, such as glass, polycarbonate, a touchscreen or filter is bonded directly to the front of an LCD panel. The process involves using a specially formulated optical compound to fill the air gap between the substrate and the LCD.

This has several major benefits:

– by filling the air gap between the LCD and the substrate, refraction and reflection of light between the layers is Removed, greatly improving the legibility of the display in direct sunlight. By using an anti-reflective substrate reflection can be reduced further.

-by using this process even a standard brightness industrial LCD can be used in demanding outdoor applications- eliminating the need for costly and notably unreliable high brightness LCD panels.

– the bonding also acts as a barrier to stop the build up of condensation between the LCD and substrate (which is another common problem with outdoor applications caused by frequent temperature changes)

– The bonding has a wide temperature range making it suitable for the toughest environmental applications. The compound used also acts as a UV shield to protect the LCD from sunlight induced damage.

– by using optical bonding in conjunction with an LED backlit panel you can greatly reduce your energy consumption in comparison to a comparable high bright product, making it a great solution for mobile battery powered devices.

– the type of panel & substrate used is important and CDS can specify a solution dependent on the application. CDS can tailor the solution to meet your project needs, timescales, and budget….

COME AND GET IT!!!

For more inforation please email bartram@crystal-display.com