In-glass laminated transparent displays improve safety and ergonomics in cockpits and other driver environments.

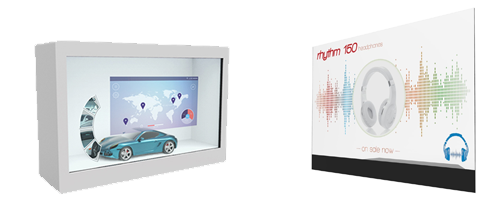

An in-glass laminated TASEL® display is basically “just” a transparent display, which is based on the proven Thin Film Electroluminescent (TFEL) technology of Lumineq, adapted for lamination purposes. With a casual glance, a non-laminated TASEL display looks just like a sheet of thin glass with a flexible printed circuit cable bonded to it. In a normal glass lamination process, the display is sandwiched between two glass sheets, usually involving a PVB (polyvinyl butural) adhesive interlayer. The lamination process is very demanding and harsh for any electrical component, but luckily Lumineq displays have a long heritage of withstanding completely inhumane conditions.

An in-glass laminated display offers many benefits in cockpits

The benefits are numerous. Consider the following, for example: The operator of the vehicle (be it a ship, a crane or a tractor) naturally observes the outside world through the windshield. If the operator must change the line of sight every time something needs to be checked from the instrument panel (like the speed of the vehicle, distance to a target, or any other important measurement), the operator gets distracted. By placing the display in the immediate vicinity of the line of sight, distractions are minimized.

There is usually a lot of free space in the windshield, but inside the cockpit, things are getting cluttered and confined. Placing a display in the windshield maximizes the utilization of space. The laminated glass also serves as good mechanical protection for the display, the perfect “cocoon”. Inside the glass, the display can withstand anything the windshield can. You can safely wipe the display clean with the windshield wipers!

Technical details of Lumineq displays for in-glass lamination

The display is currently manufactured of glass that is 0,7 mm thin. This creates a virtually invisible display, including the glass edges. The maximum size of one display is 240 x 160 mm (approximately), but the displays can usually be stacked side-by-side, creating a larger display. The brightness of the display is usually around 100-1000cd/m2, depending on the frame rate, the complexity of the display, etc. The power consumption depends on the brightness and size of the display, but is usually from some watts to some tens of watts.

There is also an on-glass laminated alternative, optically bonded, display is basically a glued-on alternative to the in-glass version. The biggest difference when attaching the display on glass is that you must design a small frame to cover the tiny 1-2mm threshold around the edges of the display.

The lamination process starts with the Lumineq Lamination Introduction Package

The most striking feature of an in-glass laminated Lumineq display is simply its transparency. With good optical matching and a quality windscreen, transmission of over 70 % is easily achievable for the overall structure, enabling the usage of the displays in places previously not thought possible. In many countries, the minimum requirement for the light transmission of vehicle windshields is 70 %.

For more information please visit https://crystal-display.com/products/lumineq-transparent/

Why not ask us today about our lamination packages? A great way to test out the technology!

Check out our Beneq Transparent EL displays.

If you have any questions or would like any additional information, pricing or datasheets, please contact us via info@crystal-display.com or call +44 (0) 1634 791600.