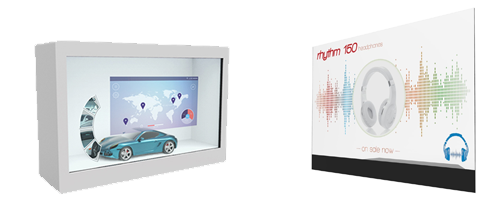

Have you checked out the in-glass laminated transparent displays yet?

Interested further? Then why not learn about the lamination process and how to start your own in-glass integration project?

So far, the incredible transparent in-glass laminated Lumineq displays have been integrated in; vehicle windshields, train windows, naval bridges and architectural glass. However, the number of potential application areas is never ending.

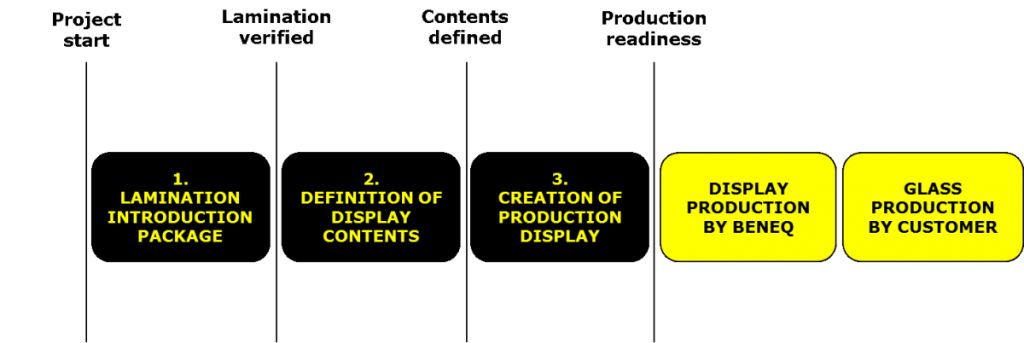

See below from a LIP to full-scale production the Lumineq Displays in-glass lamination process steps.

-

Start with a Lumineq Lamination Introduction Package

Customers can start with a “LIP package”, short for Lamination Introduction Package. This is an excellent product for trying out lamination for the first time.

Many LIPs are available but the most popular is based on a Lumineq ELT40S display panel.

The package contains a transparent segmented Lumineq ELT40S display with the necessary driving electronics and flex cabling. The difference with a standard Lumineq ELT40S display is that in the package you will find only the display on a 0,7mm glass pane with no cover glass or any other enclosure. Also included are non-functional mechanical samples (dummy displays) for the very first trials of placing glass panes between the interlayers.

-

Define the contents for your customized Lumineq display

After trials, customers are usually keen on experimenting with what they would like to show on the laminated display. For the content definition phase, there are many options. We have demo displays and reference designs available for planning the display segments.

It is also possible to use a transparent matrix display as a part of the design process. These are slightly less bright than segmented, but they offer more flexibility in testing different options and ideas for the contents of the laminated display.

-

Design the final production display to be laminated

After full understanding of the lamination process and requirements for the display contents is completed the final production design can be created. For this stage, segmented displays are typically selected because of their superb brightness, although for certain applications with less challenging transmission, ambient light and contrast requirements, a matrix display will work just fine, too. The driving electronics, interfaces and cabling are also finalized at this stage.

Ready for full-scale production

After the three lamination process steps, the new customized transparent display is production ready. The work then continues with optimization work for both the display production and the lamination and integration process at the customer facilities.

For more information please visit https://crystal-display.com/products/lumineq-transparent/

Why not ask us today about our lamination packages? A great way to test out the technology!

If you have any questions or would like any additional information, pricing or datasheets, please contact us via email or call us on +44 (0) 1634 327420.