The Basics

An LCD display is an evenly lit rectangular shape made up of smaller rectangular subsections of this shape which are called pixels. The light in the pixels is dimmed and passed through different colour filters which creates a small area in a share of a solid colour, a subpixel.

Subpixels are lined up next to each other in such a high density that our eyes cannot distinguish each individual subpixel. This makes the subpixels’ colours flow together – creating millions of different colours.

The Four Elements Needed for an LCD Display

-

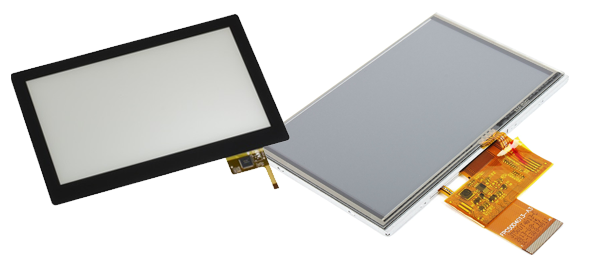

The Panel

Ultimately the panel is a large piece of grey glass or polymer sheet which dims the pixels. There are many different ways it can do this but the polarization layer is the method used in all the LCD displays today. Light always travels in a certain direction, but it can be rotated along the way, this rotation of light waves is called polarization.

In LCD displays there is such a thing as a polarizing filter. This filter will only let light through that is angled, or polarized, at a certain angle.

LCD displays have two polarizing filters behind each other both attached to a glass sheet. Between the polarizing filters are liquid crystals which have the quality of bending light. So, in an LCD display light comes from the backlight and hits the first polarizing filter. It then passes through the liquid crystals where the light is bent a certain amount before it passes through the second polarizing filter.

The liquid crystals can actually be controlled with voltage. The amount of voltage used decides how much light is bent and stopped by the second polarizing filter. This is how voltage controls the light traveling through the panel. But for a working LCD display, you need light waves which is where the backlight comes in.

-

The Backlight

The backlight to an LCD display is the source of light, it needs to be white because the emitter delivers light to all subpixels, which are red, green and blue. This white light is usually produced by either CCFLs or LEDs. CCFLs produce fluorescent light using mercury and LEDs don’t and so are much greener.

Both CCFLs and LED have a downside. They are both either point or line light sources. The light however needs to be distributed over a much larger surface and so LCD displays use diffusing and reflecting layers. Diffusers spread the light beams to cover the area they need to light up. Light then travels through a series of unevenly spaced bumps after which the diffused light either travels forward to the actual LCD panel or back. When diffused light travels back it hits a reflector. A reflecting layer guides otherwise wasted diffused light back towards the LCD display panel. A reflecting layer helps increase efficiency of the LCD display.

-

Power Supply

An LCD display requires voltages that are not usually available in the average building and so a power convertor is needed.

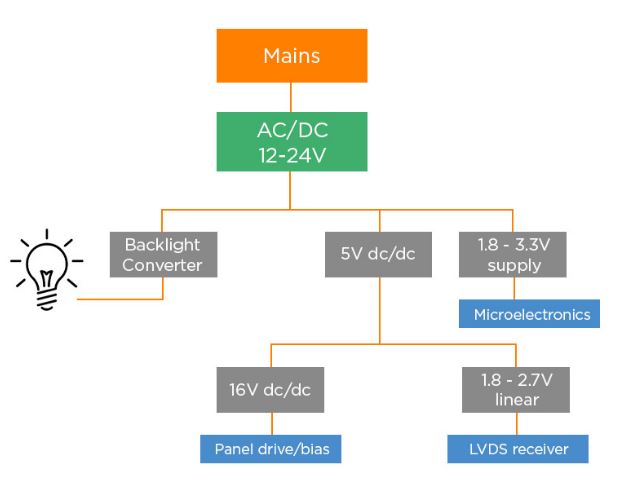

The main voltage is converted to intermediate DC voltage, usually between 12 and 24V. The power flow then separates to the backlight and the microelectronics. The 5V for the display’s electronics is once again divided into two going to the LVDS receiver and the bias driver.

-

Micro-electronics

Inside an LCD display you will find the micro-electronics which are the electronics involved in signal processing. They usually split up into two functions – the video signal receiver and the panel driver.

To check out our full range of LCD TFT displays range please visit our LCD Webpage.

For more information including pricing and a data sheets please email info@crystal-display.com or call our main office on +44 (0) 1634 327 420.