A Guide to Choosing The Best Industrial Panel PC

What should you consider when choosing an Industrial Panel PC?

Choosing the perfect industrial panel PC can be a daunting task, given the myriad of options and specifications available. Whether you’re upgrading your current system or starting a new industrial automation project, selecting the right panel PC is crucial for ensuring optimal performance, reliability, and efficiency—especially for human-machine interface (HMI) applications.

With various factors to consider, from understanding specific application requirements to evaluating hardware specifications and environmental conditions, it’s essential to equip yourself with the knowledge needed to make an informed decision. Let’s walk through the key considerations that will help you select the best industrial panel PC for your operational needs.

Define Your Application Requirements

Start by clearly defining the applications you’ll be running on the panel PC:

- Type of Applications: Are you using the panel PC for data visualization, process control, or machine interfacing? Different applications may have different performance requirements.

- User Interaction: Consider how users will interact with the device. Will you need a touch screen, or will it primarily be used for monitoring?

Evaluate Performance Specifications

Performance is critical for ensuring that your panel PC meets operational demands:

- Processor: Choose a processor that can handle your application’s complexity. Options range from energy-efficient ARM processors to powerful Intel Core i5 or i7 processors, depending on your needs.

- Memory and Storage: Ensure adequate RAM (at least 4GB) and opt for solid-state drives (SSDs) for speed and reliability in data-intensive applications.

Assess Durability and Environmental Suitability

Industrial environments can be challenging, so durability is paramount:

- Ingress Protection (IP) Rating: Look for a panel PC with a high IP rating (e.g., IP65 or higher) to ensure it can withstand dust and water exposure.

- Temperature Range: Ensure the device can operate effectively within the temperature range of your specific environment, especially in extreme conditions.

Consider Display Quality

The display is the primary interface, so it’s vital to choose one that suits your environment:

- Screen Size and Resolution: Larger screens with higher resolutions (Full HD or 4K) provide better visibility and usability for complex applications.

- Touch Technology: Decide between resistive and capacitive touch screens. Capacitive screens often offer superior responsiveness and multi-touch capabilities.

Connectivity Options

Robust connectivity is essential for seamless integration:

- Ports and Interfaces: Check for adequate USB, Ethernet, and serial ports. Consider future expansion needs and ensure compatibility with existing systems.

- Wireless Connectivity: Features like Wi-Fi and Bluetooth can enhance flexibility and remote access capabilities.

Why Choose CDS?

Choosing Crystal Display Systems Ltd means opting for quality, innovation, and dedicated support. With their range of customizable solutions and commitment to excellence, CDS is well-equipped to meet your industrial panel PC needs and help drive your operations forward.

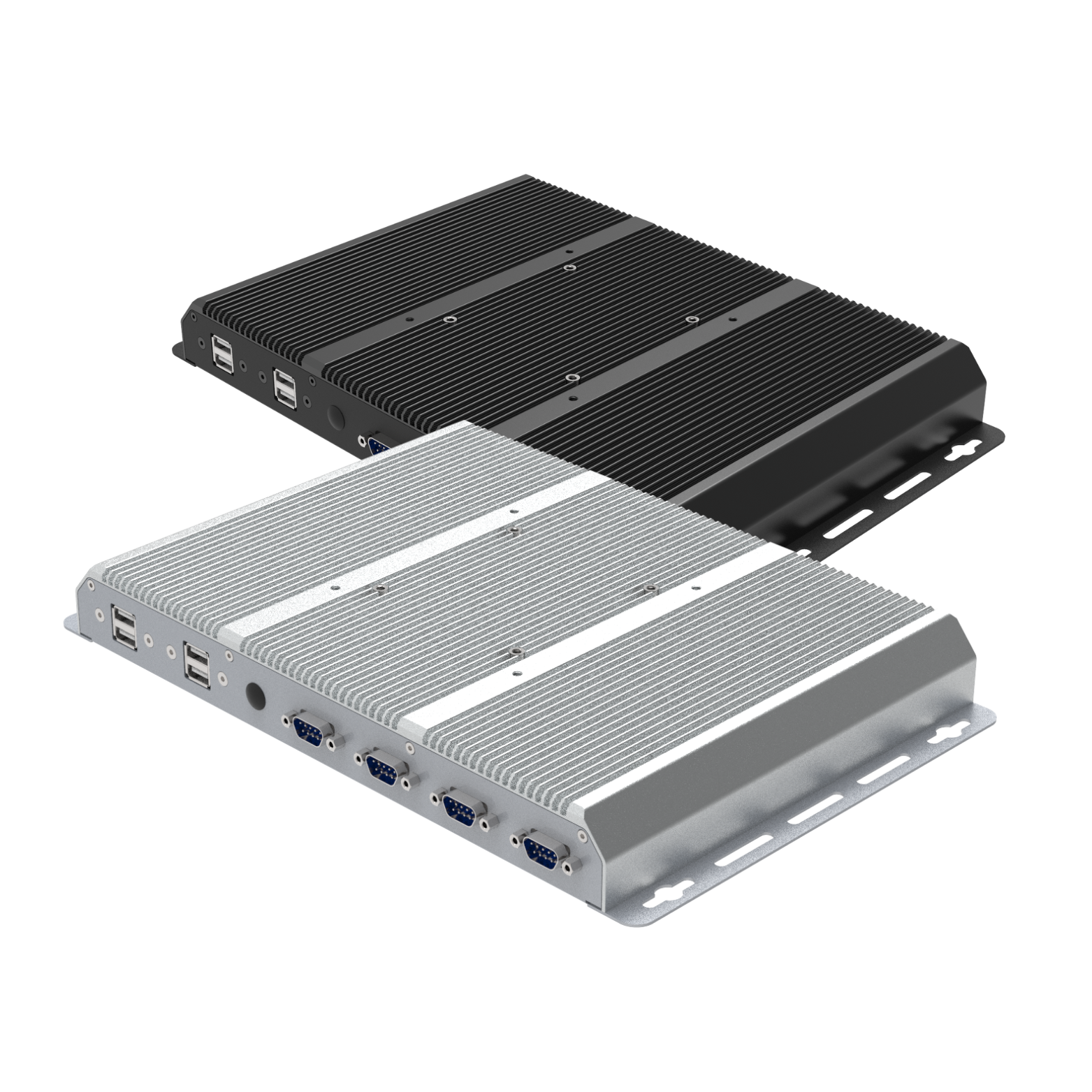

Take a Look At Our Industrial Panel PC's in Action

Need More Information?

CALL US +44 (0)1634 791600