Improve clarity and Ruggedness with Optical Bonding

At Crystal Display Systems, we understand that improving optical clarity, durability, and efficiency is crucial in TFT display technology. Optical bonding is a key innovation that addresses common design challenges, enabling displays to perform optimally in demanding environments, from industrial and medical settings to outdoor and defence applications. As optoelectronics continue to evolve, optical bonding remains essential for the next generation of high-performance displays.

The Optical Bonding Process

Optical bonding involves filling the gap between the display and its protective cover glass with an optically clear adhesive (OCA). This process addresses key challenges such as glare, durability, and operational efficiency by reducing internal reflections, increasing structural integrity, and enhancing visibility.

Basic Principles of TFT Displays

TFT displays are advanced optoelectronic devices composed of three primary layers:

- Backlight (Light Source): Typically, an LED array, this component determines brightness, energy efficiency, and display uniformity.

- Liquid Crystal Layer: Modulates light transmission based on electrical signals from the TFT matrix.

- Front Glass and Polarisers: Control light behaviour, reducing glare and improving contrast.

Key performance factors include:

- Wavelength Selection: LED backlights must emit at optimal wavelengths to enhance colour reproduction and minimize energy loss.

- Brightness and Efficiency: Displays must provide sufficient luminance for readability without excessive power consumption.

- Signal Control: Precise electronic management of the TFT matrix ensures sharp and accurate images.

Challenges in TFT Display Design

Despite their versatility, TFT displays may face performance limitations due to environmental conditions and suboptimal assembly. Common issues include:

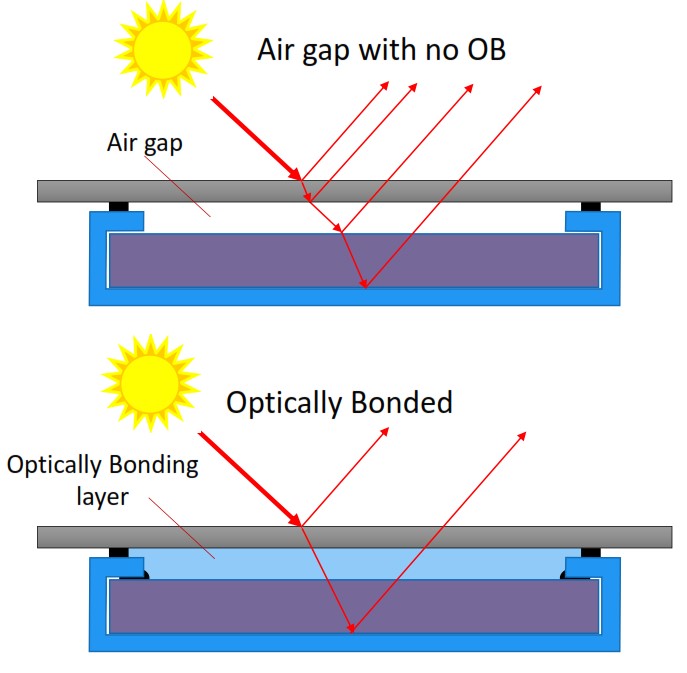

- Reflections and Glare: Ambient light reflections reduce readability. Air gaps in display assemblies increase internal reflections.

- Durability: Displays can be vulnerable to shocks, vibrations, and moisture exposure.

- Light Leakage and Loss: Poor assembly techniques reduce light efficiency, diminishing brightness and uniformity.

- Heat Build-Up: High operating temperatures can negatively impact performance and lifespan, especially in outdoor environments.

Advantages of Optical Bonding

Optical bonding enhances the interaction between light and electronics, optimizing TFT display performance in several ways:

- Enhanced Optical Clarity: Filling the air gap reduces internal reflections and improves light transmission, leading to:

- Increased brightness as more light reaches the user’s eyes.

- Improved contrast, particularly in bright environments.

- Improved Durability: The bonded layer enhances structural integrity, providing:

- Greater resistance to shocks and vibrations, crucial for industrial, transport, and military applications.

- Moisture protection by sealing sensitive components against condensation.

- UV protection, as some bonding gels filter harmful ultraviolet light, preventing screen blackening.

- Wider Viewing Angles: Eliminating air gaps minimizes light scattering, preserving colour accuracy and image quality across broader angles. This is essential for medical and public information displays.

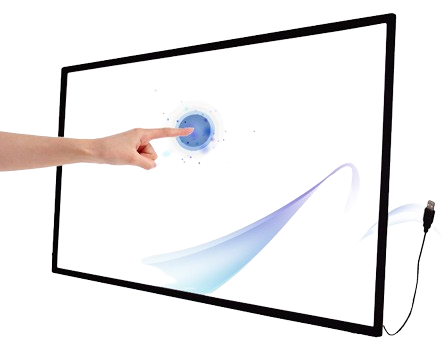

- Reduced Parallax: By aligning the display and cover glass more closely, optical bonding improves touch accuracy and enhances interactive display performance.

Design Considerations for Engineers

When incorporating optical bonding into TFT displays, engineers should evaluate:

- Material Selection:

- Optical adhesives must offer high transparency, UV resistance, and compatibility with display materials.

- Cover glass should feature anti-reflective, anti-glare, and scratch-resistant coatings for added durability.

- Environmental Conditions:

- Adhesives should have stable optical and mechanical properties across varying temperatures.

- Low water absorption adhesives are ideal for humid or outdoor applications.

- Manufacturing Precision:

- Precise alignment prevents optical distortions and performance degradation.

- Adhesive curing processes must avoid defects such as bubbles or discoloration.

- Lifecycle and Reliability:

- Comprehensive testing should include brightness, contrast, and environmental stress assessments.

- Engineers should consider repairability in the event of component failure or damage.

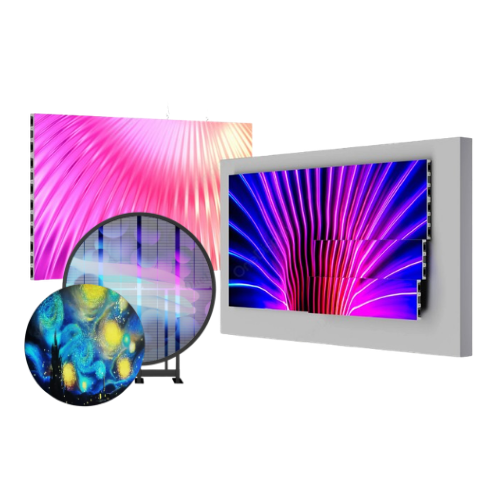

Applications of Optical Bonding

Interactive Kiosks Benefit From Optical Bonding

Optical bonding is invaluable in applications that require consistently high display performance:

- Medical Equipment: High brightness and wide viewing angles improve usability in operating rooms. Some applications may require electromagnetic interference (EMI) shielding.

- Industrial Equipment: Enhanced resistance to shock, vibration, and harsh environments ensures long-term reliability.

- Defence Systems: Optical bonding improves impact resistance, adapts to temperature changes, and offers optional EMI shielding.

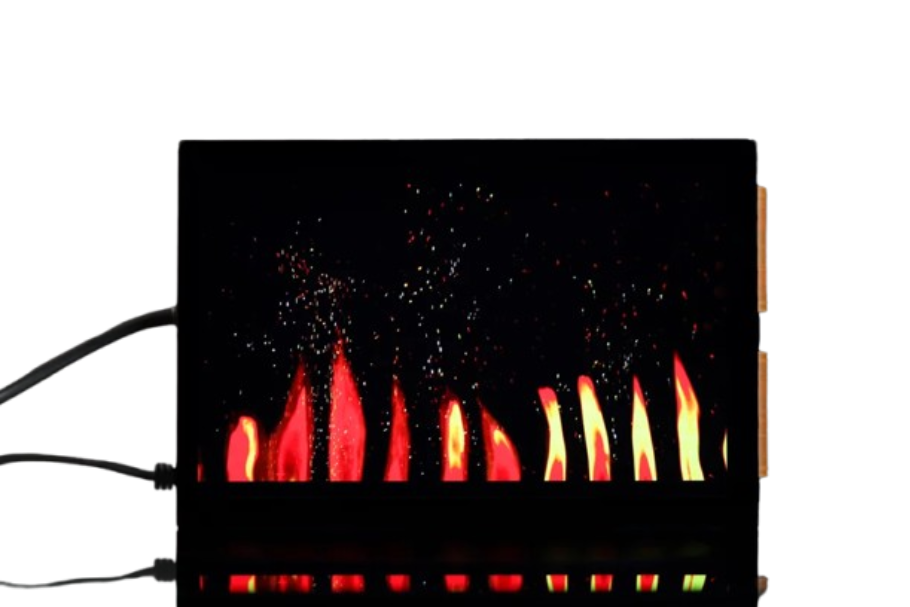

- Transport Displays: Used in vehicles and outdoor settings, optical bonding enhances glare reduction, durability, and legibility in bright conditions. It also reduces display blackening and minimizes the need for internal cooling fans.

- Outdoor Signage: Increased brightness and contrast improve readability under direct sunlight.

By improving optical clarity, durability, and efficiency, optical bonding is a key innovation in TFT display technology. Addressing common design challenges, it enables displays to perform optimally in demanding environments, from industrial and medical settings to outdoor and defence applications. As optoelectronics continue to evolve, optical bonding remains essential for the next generation of high-performance displays.